In part 1 of this article, the edge geometry associated with the deliberate “raising of a burr” was described. As noted, the thickness of this burr was several microns. For shaving, we are targeting an edge width (keenness) in the range of 0.1 micron or less. If we were to “break off” this burr, the edge profile would be far coarser than is achieved with even the lowest grit stones typically used in straight razor honing. For that reason, the raised-burr is not desirable to straight razor honing.

In the typical honing progression on a flat hone with edge leading strokes, alternating sides, a triangular bevel is formed, terminating at a width determined by the level of “micro-chipping” that occurs at the apex. A burr, as defined by “metal beyond the apex” does not form; the raised-burr is easily avoided. However, other forms of “finishing” burrs can be produced and some examples are described here.

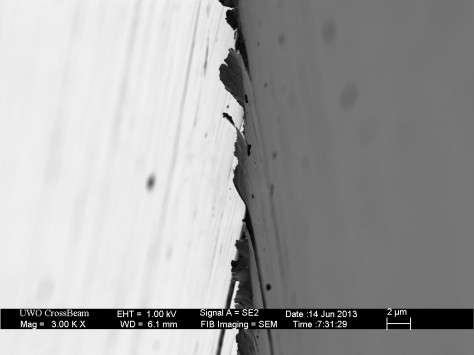

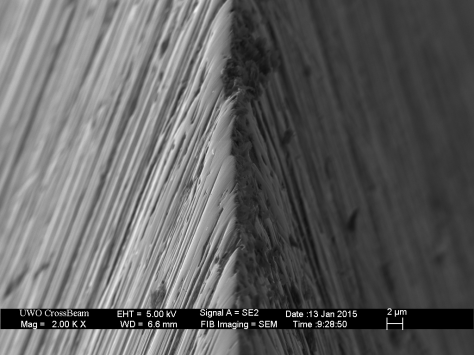

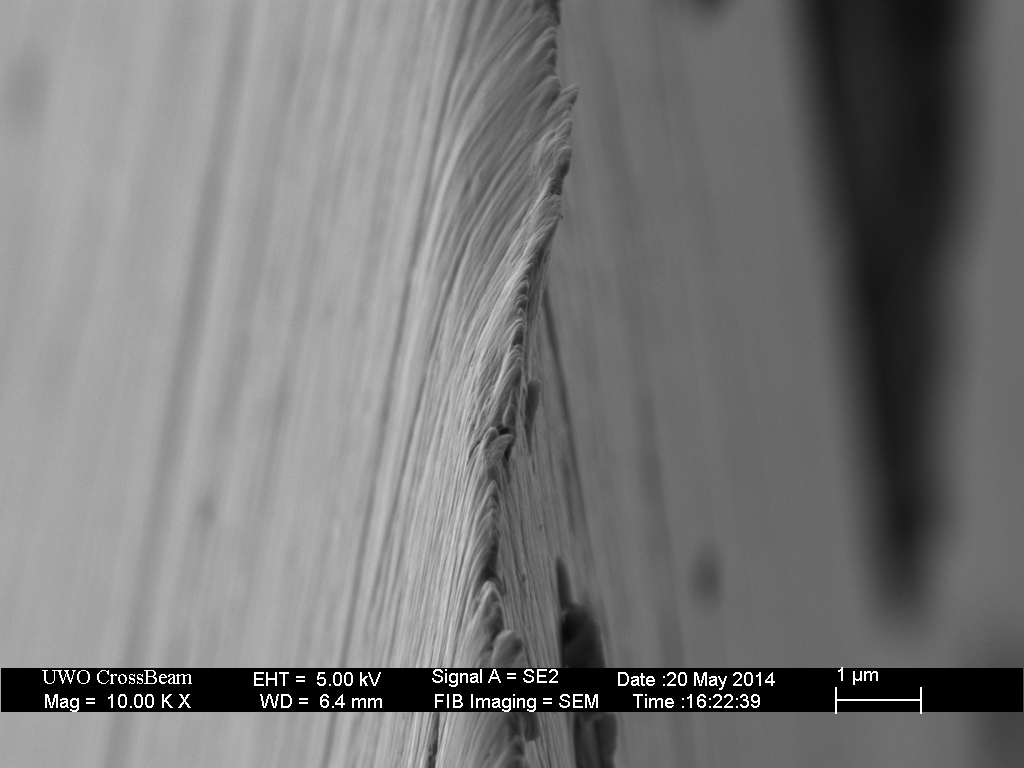

Shown in the image below; a straight razor honed to the Shapton 8k level, prior to stropping. The edge width is in the range of 150-200nm, slightly greater than the threshold for comfortable shaving.

With sufficient stropping on clean linen/leather, an 8k edge can be brought to shaving-level keenness. Few people have the patience for this. The addition of sub-micron abrasive to the strop will greatly accelerate this process; however, if done “incorrectly” can produce a very undesirable burr.

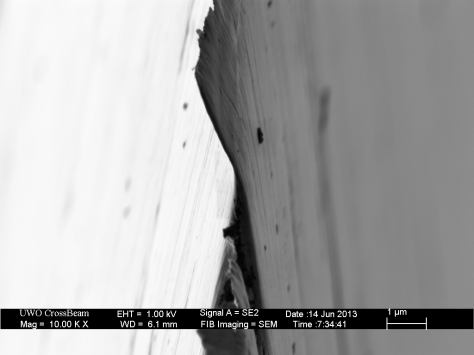

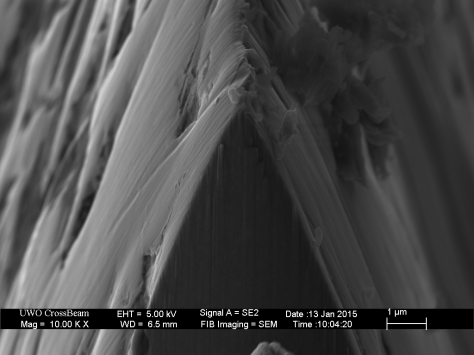

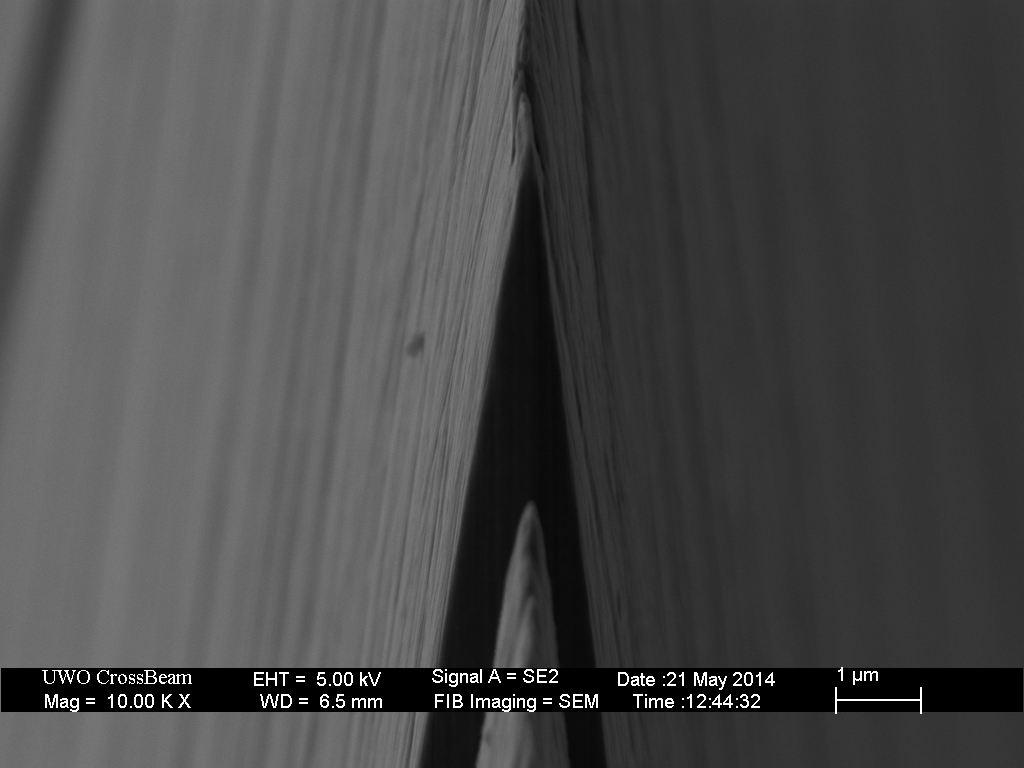

This foil-edge burr can be reduced, but not eliminated, by increasing the number of laps; shown below after 100 stropping laps.

Fortunately, this foil is fragile enough to be completely removed by a few strokes of beard shaving and the edge width after breaking off the burr is well below the threshold for comfortable and efficient shaving.

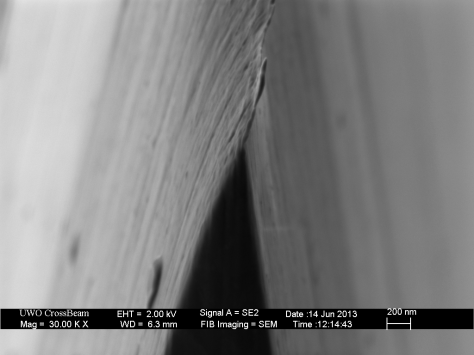

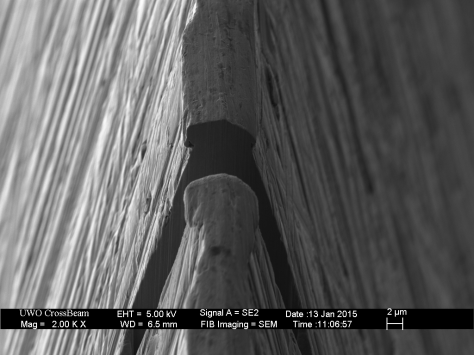

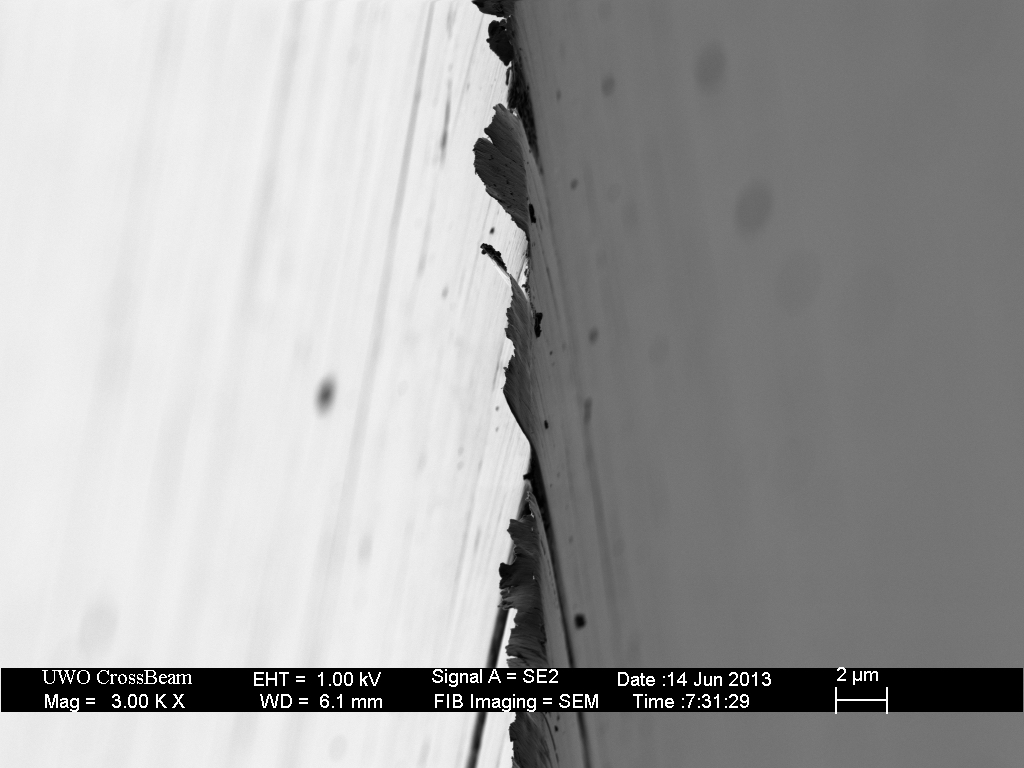

As a starting point, these experiments and the discussion have been limited to carbon steel straight razors; however, the same principles apply to knife sharpening. The primary difference being that a knife edge must be more robust than a razor and therefore have a larger bevel angle. Below, is the edge of my H1 steel pocket knife, sharpened with an approximately 1500 grit ceramic stone at 20 degrees per side.

The rough burr is easily removed by stropping on a diamond-impregnated kangaroo leather bench strop, shown below.

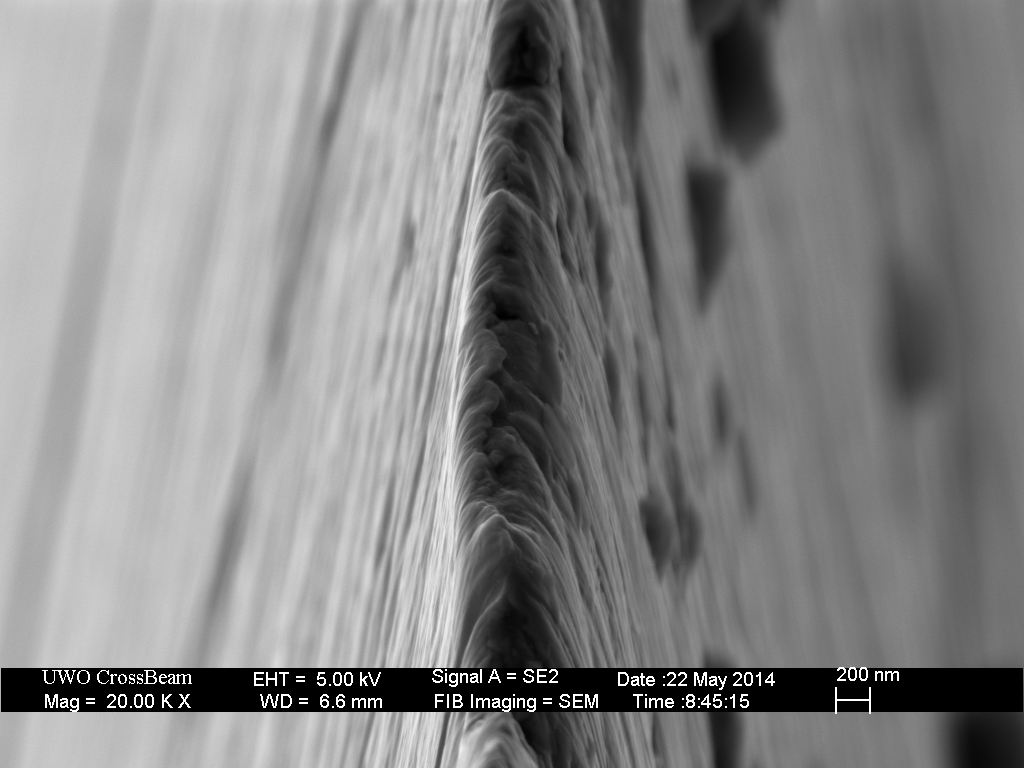

A close-up view reveals that a slight foil is present at the apex.

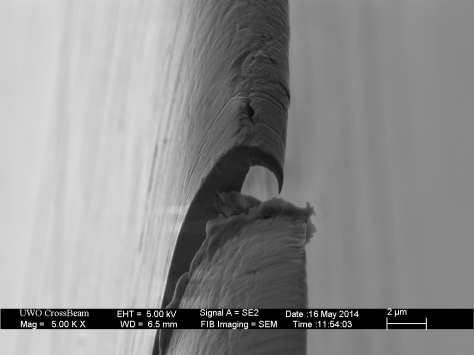

The significance of this foil edge will of course depend on how the knife is used (or abused). Shown below is the same edge following the cutting of some heavy cardboard. Clearly, burrs and foil edges are of no consequence in this case.

A similar experiment is shown below for a straight razor with a foil edge.

Following stropping, a few centimeters of bond paper were cut, removing the foil, unfortunately also destroying the cutting edge. The effect cutting of paper could be described as forming a “folded burr.” Another view is that the blade was simply used for a purpose requiring a larger (stronger) bevel angle.

In the above examples, I have shown burrs where the “unwanted metal” is beyond the apex. Another possibility is that the steel fails, or is removed during normal use. This observed loss of keenness is often attributed to the presence a foil edge or sometimes described as an “over-honed” edge.

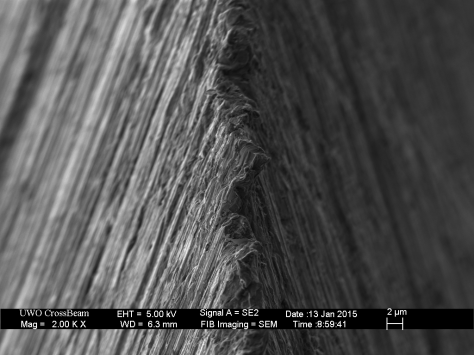

In the example below, the razor was honed to a 20k Suehiro Gokumyo, an edge which just achieves shaving-level keenness prior to stropping. The reader will be forgiven for being unable to observe a difference from the 8k edge.

Stropping on (clean) leather produces a very subtle improvement; shown below after 300 and 500 laps.

In contrast, stropping (lightly) on clean linen causes the edge to break off, resulting in an edge width too large for comfortable shaving. Without the accompanying images, this effect would likely be attributed to the presence of a foil edge that has broken off with stropping. We should consider whether a foil-edge burr can be defined as any part of the apex that does survive the intended use.

In the examples presented here, I have highlighted some of the issues that have been observed during various experiments. More detailed discussion will be provided in posts specific to those experiments. The images presented here are intended as discussion points, with the expectation that a “part 3” will appear in the future.

24 responses to “What is a burr? – part 2”

Wow man this is stellar….Thanks for your time in doing this! so a few questions I have:

1. What is your recommendation for minimizing/removing the bur once you have already developed one? There is some controversy about folding the burr over with a dowell rod and then cutting it off w/ your stone vs. just using a few alternating high angle passes (email me for references).

2. If you do not develop a bur but use alternating passes the whole time, how do you know you have hit the apex *for sure*?

3. What does increasing or decreasing the stropping angle do when using the stone angle as the reference point?

keep up the great work!

LikeLike

I don’t have a simple answer for you on this. My experience is that removing a burr requires a reduction in keenness. The obvious options are to either avoid forming a burr, or to restore the keenness after removing the burr.

I hope that the pasted-strop articles will provide some clarity for you, when they are complete.

LikeLike

You should explain how many strokes are correct on linen and leather to a correct shave

In my opinion honing without forming a burrs is difficult to understand!

Is it possible to form teeth without burrs capable to shave? I doubt is possible. And if it is possible can I use a method that not uses a microscope? In my opinion it is possible but I don’t see difference in teeth created from burrs and without burrs. If a teeth is a teeth where is the difference? Have you experienced it?

LikeLike

I’m looking forward to it. I specifically wonder what would happen if you could reduce the stropping angle by 2-3 dps… would that still create a foil edge as shown above? Thanks Todd.

LikeLike

For a straight razor, we cannot reduce the stropping angle, since the spine is already in contact at the honing angle. However, the choice of strop substrate is another parameter.

LikeLike

What if you were to use 2 pieces of electrical tape on the spine, such as what Tom at Jende Industries does sometimes, and then when you transition to strops you can remove the tape? I actually sharpen my straight razors on the wicked edge (w/ some special fabricated extras ;)) so I do it all the time but I do understand the dilemma for traditional sharpening.

LikeLike

Great post! Thanks for the effort. I’m totally unaware of the usage of a SEM microscope, and preparation of the samples, but some of the pics’ explanations show that you performed a thorough job before even switching the SEM on.

LikeLike

I already know from experience than cutting cardboard can severly blunt a knife, but I didn’t imagine that cutting paper with a razor blade would damage the razor that much!

It’s interesting to see that it if one is going to be cutting cardboard then there’s no point in stropping the knife beforehand. What if the knife were to be used to cut meat or vegetables; is it worth stropping the blade in that case? Is removing the burr on a kitchen knife really that important, and does it make a difference whether I remove the burr by gently slicing into a piece of soft wood or by stroppiing on a bench strop?

Cutting paper with a razor blade is not normal use, but how much wear does a razor blade suffer from a beard ? How many comfortable shaves can you get from your razor before you need to strop it again? Is stropping sufficient to restore the blade to shaving condition? How many shave/strop cycles can you do before the blade gets so worn that you need to take it back to the stones?

LikeLike

I would be cautious in drawing any conclusions from these examples; I chose them only to illustrate a few types and dimensions of burrs that may occur.

Blade wear from shaving is going to vary from person to person, just as it does for commercial blades.

In the future, I will document the life-cycle of a straight razor with my personal use and stropping.

LikeLike

Real cool post again! Love the pics. Please keep it up. By the way I got bored and solved the whole shapton glass overhoning thing..yes.. they will “overhone”.. they made a pretty poor mathematical error and I dont want to mess with your blog (still my favorite stones). Bored physicist with nothing going on at the moment. On the current topic If you could get your hands on some of the 3m diamond lapping films I would love to see some pics using these.

LikeLike

I would be curious to know your thoughts on “overhoning.” My feeling is that the concept is based on an incorrect view of what happens to the apex during honing, but I am not convinced that there is a consensus on what overhoning actually is.

I have done a fair amount of experimenting with lapping film and will try to put together a discussion in the future.

LikeLike

Great discussion.. I’m quite impressed with the SEMs and the interpretations… Still having some difficulty understanding what could happen with “overhoning”.

LikeLike

Thank-you, and if you do learn what “overhoning” is, please let me know.

LikeLike

The edge begins to chip out after a large number of strokes. Here are some pictures.

https://jendeindustries.wordpress.com/2011/10/30/shapton-16k-straight-razor-edge-chipping-controversy/

LikeLike

The link to Tom’s blog that BBrian offers, and the concurrent discussion with Sham is best read after reviewing the Shapton 16k edge micrographs in

The Pasted Strop part 1

LikeLike

This was a great read, even if much of it was confusing to a newbie. One thing that gets me though is all the folks who will insist they can go a month or longer before having to switch blades on their Gillette 🙂

LikeLike

I think these photos are fabulous. It’s what I’ve always wanted.

I use a 20x loupe to get some idea of what’s going on [while using my diamond stones, ceramic stones or strop] but I knew that I was still in the dark about the actual apex. I never use the loupe to look at results from knife steeling…there I only look at performance.

The pocketknife cardboard photo in particular interest me. I’m mostly interested in knives for kitchen use, where I have found a steel useful. The mushroom cross section seems to me to be something that an edge leading pass on a steel would really fix. And it may explain why edge leading knife steeling sometimes works so well.* Whereas if I wanted to realign edges, I might think of a strop instead.

* One of my tasks is cutting a sausage patty from a tube of raw breakfast sausage: if the knife is dull it simply creates a dent and pulls back the edge of the plastic wrap (loose end from previous cut). I imagine my edge (contrary to what we often here about “misaligned edges” may simply be dulled in the same way that this pocket knife was…I do baby the edges: only one point of the knife ever touches the cutting board)

Anyway, Thanks for all the great work,

Sincerely, Mark

LikeLike

The images are so clear, I wish I could just take a pair of microscopic scissors and trim off the Burr.

LikeLike

My question here is about “overstropping” Don’t know if it exists but I see something on my optical scope that I have questions about. It appears after linen and leather, the burnishing effect seems to pull metal to the edge as you showed in a pic above. If I could post a pic I would. It looks like if you were frosting a cake and you put a large blob on top in the center then took your spatula and started to spread the frosting to the periphery.

LikeLike

Matt, I watched your last video, (I subscribe) and you said stropping on linen and leather causes micro-convexity, but the above evidence says otherwise. How can it be?! Love the Jnat videos!

LikeLike

The example showing the effect of clean linen represents the early stages of forming micro-convexity. In general, stropping applies higher pressure to the near apex region of the bevel face, resulting in micro-convexity. The addition of micro-abrasives to the strop essentially just speeds up the effect, and therefore we do not observe the subtle burnishing effect shown above.

LikeLike

The scale of burnishing I show is only visible with the best SEM and the most skilled operator. You will never see this with an optical microscope. You are almost certainly seeing a foil edge, which is the result of UNDER-stropping.

LikeLike

I would very much like to see how single bevel edges fair under the SEM regarding stropping, burrs, and such.

Personally I am interested in getting the right edge on grafting knives(orchard trees) which geometry wise are a smallish pocket knife with a bevel between a sushi knife and a wood chisel, and fairly square profile like a straight razor. They need to be very keen to make a flat smooth surface without disturbing the bark so the right type of cells can be in contact and fuse together and strong enough for fresh 5-15mm branches. Most grafters carry pocket hones in the field. Some use double bevels, but single just makes a flatter surface and doesn’t seem to climb out of certain cuts as easily.

LikeLike

Great article man.

It would be nice to compare results if you apply the compound to hard surface like wood or paper over glass. Maybe on hard surface de behavior changes to something similar to stone and avoids forming foil edges.

For knife sharpening I would be interesting to compare low grit compound with stone.

Pasta Jacare Black compound has relative grit 1.5k and brown compound 6k.

From practical experience results seem very similar but no idea how it would look under a microscope.

LikeLike