The first step in a honing progression is the “setting of the bevel” with a coarse hone, typically in the 1k grit range. This step is usually considered to be the most important in the honing progression, and therefore the place to begin this study.

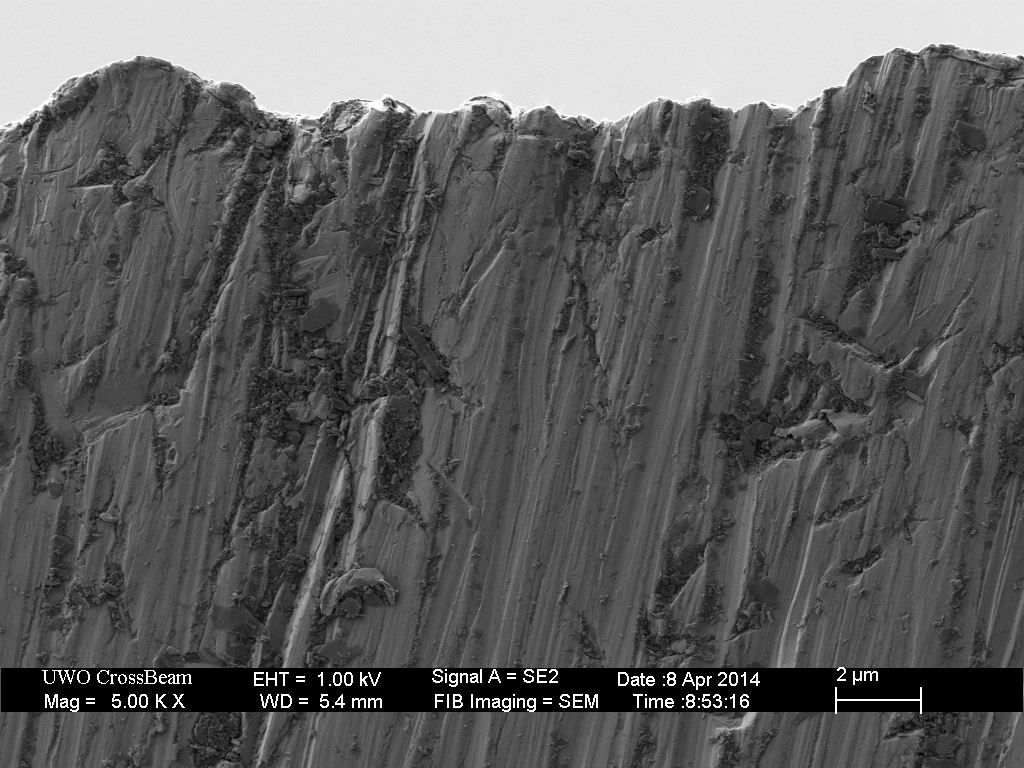

A comparison of two commonly used bevel setting hones; a DMT1200 diamond plate and a Chosera 1k hone. (This experiment was performed with edge-leading strokes only, please see The Pasted Strop part 1 for a comparison of edge-leading and edge-trailing strokes on a Chosera 1k). Although nominally the same grit level, scratches from the diamond plate with its fixed grit are slightly deeper and well defined. The surface of the bevel following the Chosera hone displays the typical indentations from loose grit “rolling” across the surface. In both cases, scratches are in the range of one micron wide and a few hundred nanometers deep.

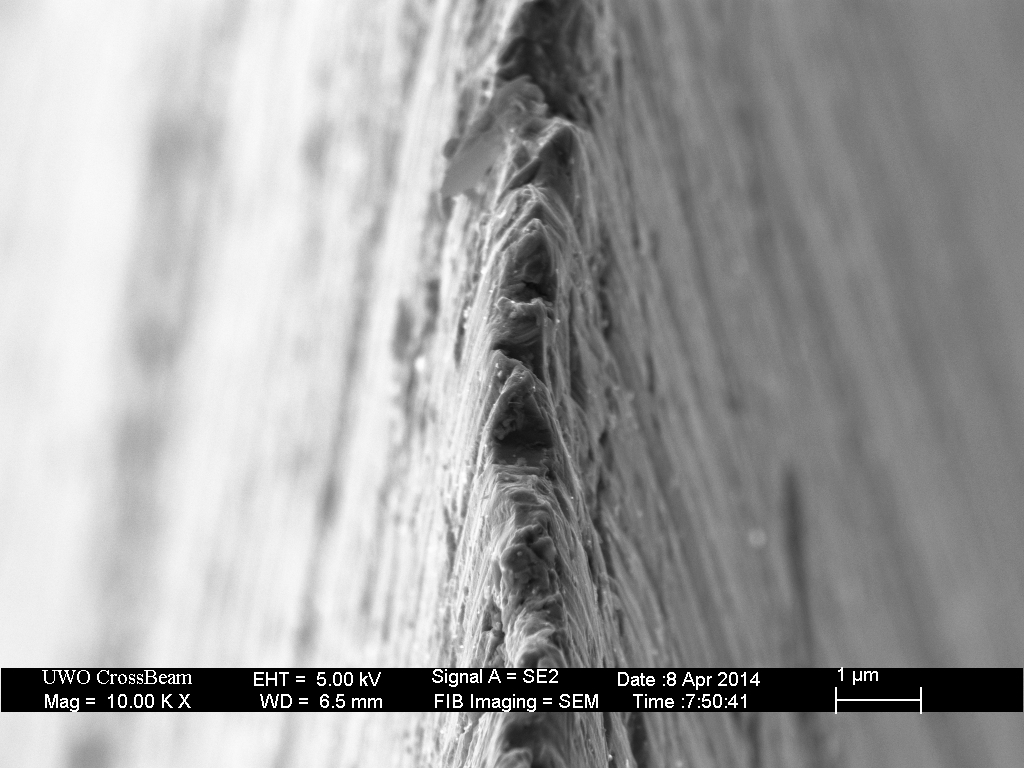

These plan view images of the bevel provide almost no information about the edge profile or the keenness of the edge. However, imaging the blade edge-on provides a clear view of the difference between these two honing results. The Chosera 1k produces an edge width in the range of 0.5 μm, while the DMT 1200 produces a much keener edge, in the range of 0.1 μm. In both cases, there is significant variation in this width along the edge.

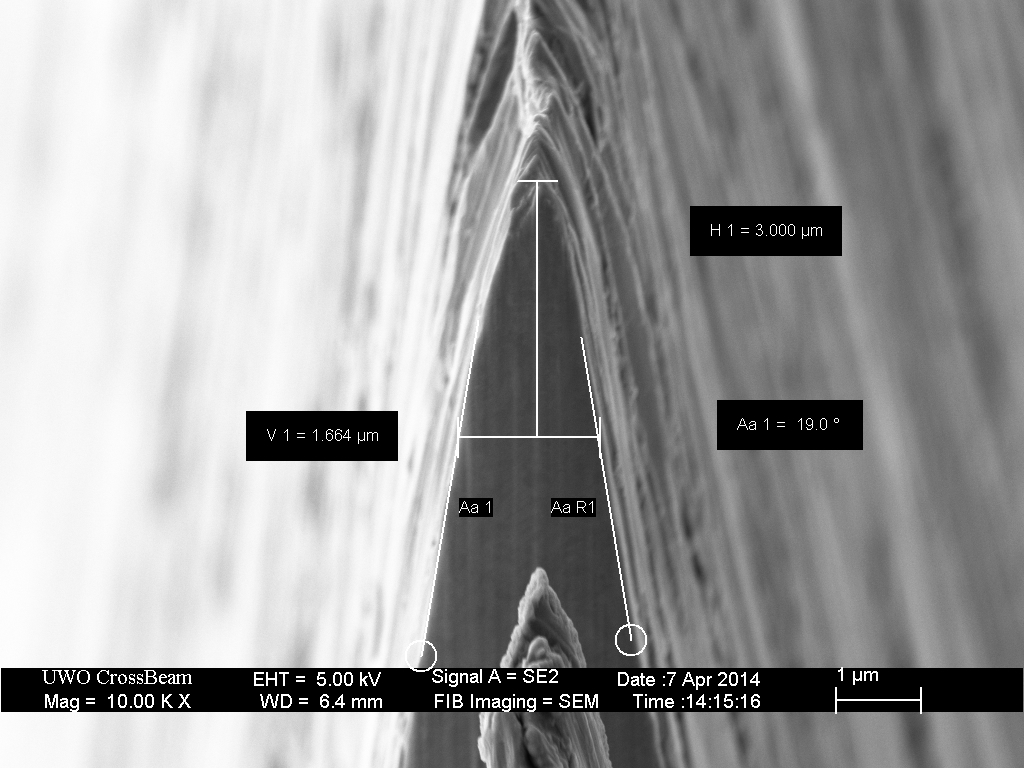

The curvature of the scratches near the apex indicates that the superior keenness of the DMT edge is result of convexity near the apex; however, this effect cannot be quantified from the edge-view SEM image alone. To visualize the edge profile and determine the extent of convexity, a cross-section of the edge is required. Focused Ion Beam (FIB) cross-sections were milled through each of the blades above, and the cross-section images are shown below.

Comparison of the two cross-section images indicates that both edges are convex near the edge. There are several methods to quantify this convexity. As the convexity produces curvature in the bevel profile, a rigorous mathematical description would require fitting the shape of the bevel to the equation for a curve. For the purpose of this study, a simpler approach will suffice; measurement of the bevel angle near the apex and measurement of the edge width at some distance from the apex. These measurements, combined with a measurement of the edge width at the apex will allow the quantifiable comparison of the edges produces by different hones, stones and strops.

In the absence of any convexity, the bevel angle should be 16 degrees, based on measurement of the blade width (15.5mm) and the spine thickness (4.35mm). Below, the calculated angle agrees with that made by SEM measurement of the cross-section image of a blade with no convexity.

To quantify the convexity of the blade, we measure the bevel angle between 2 and 5 microns from the apex. Also, the edge width is measured at a distance of 3 microns from the apex.

The measured bevel angles are 17.5 degrees and 19.0 degrees for the for the Chosera 1k and DMT 1200 edges, respectively. The widths at 3μm from the apex are 1.4 μm and 1.65μm for the Chosera 1k and DMT 1200, respectively. For comparison, a 16 degree bevel with zero edge width (a perfect triangle) has an edge width at 3μm of 0.85μm. These results confirm that the smaller edge width of the DMT 1200 edge is due to the greater convexity of the bevel near the apex.

Using our definitions of “keen” and “sharp,” the DMT 1200 edge is keener due to the narrower apex width; however, the Chosera 1k edge is sharper due to the smaller angle and narrower edge width at 3 microns. In the next post, the refinement of the 1k edge during a honing progression investigated.

It is sometimes said that 90% of honing a straight razor is done at the 1k level; the images above suggest that may be an understatement. While many heated discussions have been had on the relative merits of finishing on a Coticule, a JNat, an Escher, Lapping Film, a Charnley Forrest, a Zulu Grey, a Shapton 16k, a Gokumyo 20k or an Apache Strata, the images and measurements presented here show that it will be possible to make objective quantitative comparisons between them.

7 responses to “The Bevel Set”

[…] the bevel set on the Chosera 1k, the razor was honed on Shapton glass stones; 2k, 4k, 8k and 16k. At each step in […]

LikeLike

How did the convexity form from a non compressible medium like the Chosera 1K or the DMT plate? Was there some stropping?

LikeLike

I have a speculative explanation in this article:

https://scienceofsharp.wordpress.com/2015/03/01/the-diamond-plate-progression/

LikeLike

“As the convexity produces curvature in the bevel profile, a rigorous mathematical description would require fitting the shape of the bevel to the equation for a curve.”

Just a suggestion; how about you graph a perfect triangle over the edge of the cross-section and then use ImageJ to calculate the “unfilled” space between the triangle and the observed edge. This way you could attach a number to how perfect the edge is. (Less space to fill equals more perfect edge)

LikeLike

Do you think using an Atoma 1200 would change the results much? I’m curious, does this mean you would pick a 1200 diamond plate over a Chosera 1K for bevel setting?

Thank you.

LikeLike

It depends on what you mean by “bevel setting.” For a new razor that needs significant work, I’d use a Chosera 1k or similar with very heavy pressure. If it’s hollow ground enough to flex with heavy pressure, I would use the DMT EF – it’s very fast with low pressure. I don’t care for the feel of an Atoma 1200 on a razor. All of these will require a finer hone to clean up the apex damage.

For the sort of bevel setting required with routine re-honing, I only use the SG4k. It’s more than fast enough and doesn’t tear up the edge the way coarser hones do.

LikeLike

Since I wrote this article (7+ years ago), I have determined that there is no advantage to going that coarse for bevel-setting. I now only use a 4k Shapton Glass on my personal straight razors.

LikeLike