This is a quick update to my previous post about that “12k resin bonded diamond” stone. Apparently, I created some controversy that I would like to take a minute to discuss and clarify.

Initially, I was very surprised to discover that “resin bonded diamond” doesn’t actually mean diamond abrasive suspended in polymer, but rather the resin is what we call a “composite” material, in this case silicon carbide filled resin. I may have given the impression that there were NO diamonds in these stones, that the diamond was substituted by silicon carbide. In fact, the first location I analyzed had no diamonds of the expected size, but there was a hint of some much smaller fragments. I did another round of analysis on these stones, the results of which are presented here.

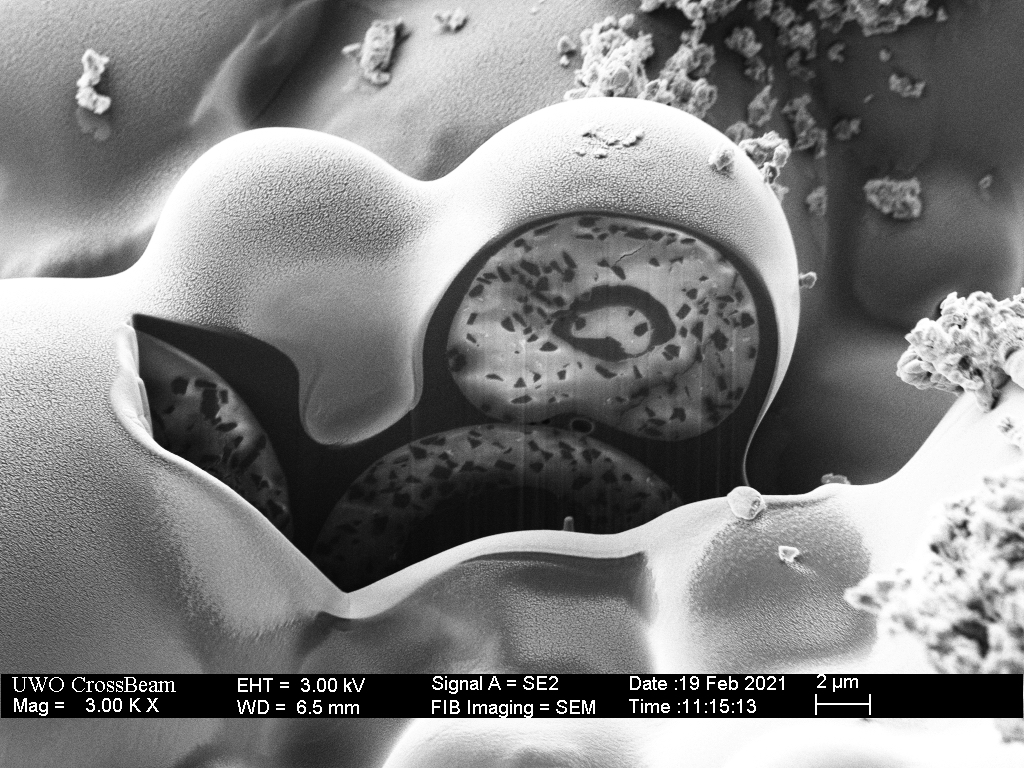

As a point of reference, the “gold standard” for 1 micron diamond abrasive is 3M diamond lapping film, which is very effective at cutting high vanadium carbide containing steels like S110V and Maxamet. Lapping film is not simply diamond mixed with polymer. This particular type is made from silica-based ceramic beads containing 1 micron diamond that are bonded to the substrate with a polymer coating. The beads are smooth with diameter in the range of 10-30 microns.

Below, I show the analysis of second (polished) area of the 12k resin-bonded stone and an analysis of a region of the 3k stone. It should go without saying, that one or two small analysis regions from one or two stones is not sufficient to quantify the character of this product in general.

The 3k stone contains diamonds near 10 microns in size, consistent with the grit rating; the silicon carbide filler particles are more abundant and slightly coarser than the diamonds.

The 12k stone does contain diamonds amongst the silicon carbide. The diamond concentration is relatively low, but mostly in the expected size range of 1-2 microns or smaller; there is one that is more than 5 microns in the top left corner of the analysis region. The silicon carbide appears to have the same particle size range as that in the 3k stone. Given this result, it is not surprising that the stone behaves more like a 2k silicon carbide stone and not at all like 12k diamond lapping film.

5 responses to “That Resin Bonded Diamond Stone: Part 2”

Seems to me, even with further investigation, this article remains aptly titled. I did learn something however, and for that, as always, I appreciate the education Todd.

LikeLike

Thanks for taking the time to share all this. I always find myself coming back to this blog because you’re able to provide such awesome images

LikeLike

It would be interesting to see an analysis of Veneev bonded diamond stones. They offer some in 25% diamond and others in 100% diamond, which begs the question … what is the binder if it’s 100% diamond? They also claim that in their gen. 2 stones they are using a non-cutting polymer binder in their higher grit stones.

LikeLike

AFAIK, the term “relative concentration” (of diamond powder in a unit of volume) is from Russian technical standards for diamond abrasives. It goes like this:

25% – 1.1 carats per 1 cubic centimeter

50% – 2.2 carats

75% – 3.3 carats

(and so on)

LikeLike

Apparently abrasives like boron carbide are sometimes used as filler in resins.

LikeLike