Ceramic kitchen knives are relatively inexpensive and are claimed to “stay sharp” longer than traditional steel knives. For this study, I purchased some “name brand” blades made by the Kyocera Japan, and some inexpensive “Gibson” brand knives imported from China by Bed Bath & Beyond, as well as a very inexpensive knife from my local Dollar Store. All of these blades were made of white zirconium oxide (zirconia) ceramic.

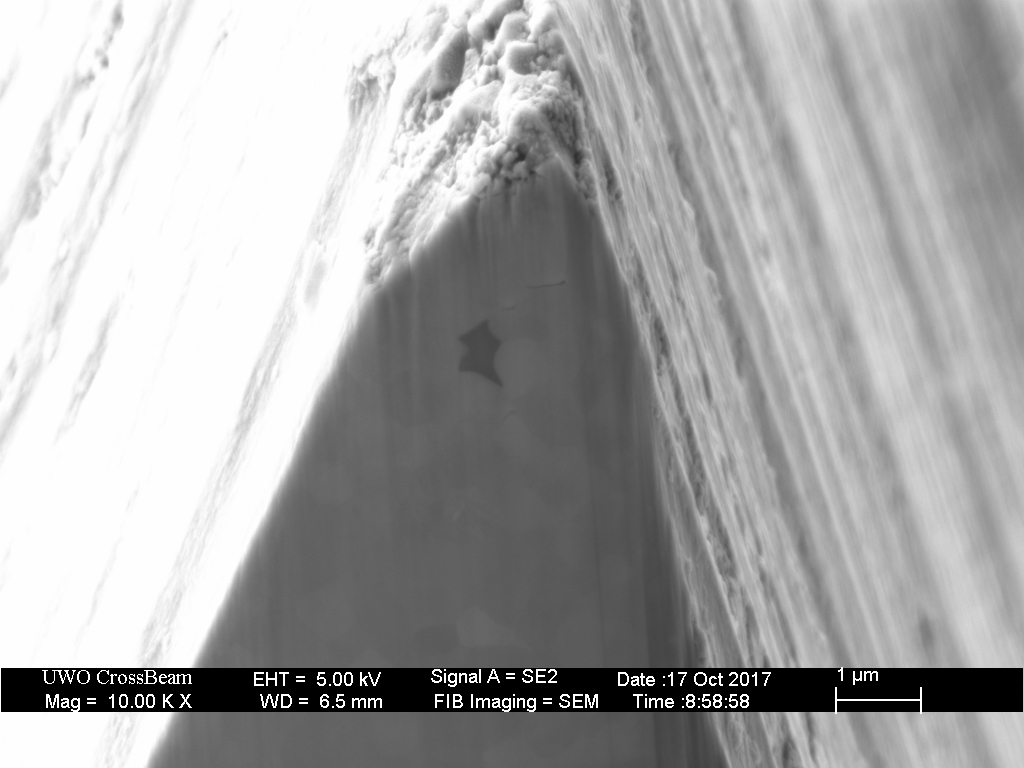

The images below show the “factory sharpened edge” of one of the Gibson knives. All of the blades studied displayed similar characteristics, with an apex width in the range of 1-2 microns (about 20 times wider than a typical razor or box cutting blade). The apex is typically flat with roughness resulting from the underlying crystal structure. Individual crystal grains are clearly visible at the highest magnifications. One or both of the apex shoulders typically displays sub-micron keenness although with an obtuse angle. It appears that the cutting performance of these blades can be attributed to the geometry of these shoulders and to the sub-micron roughness of the apex, rather than to simple geometric (triangular) keenness. Anecdotally, the factory edges on these knives were all quite effective at slicing with a draw but clearly lacked the keenness required for push-cutting paper.

All 3 brands were fabricated from Zirconia ceramic, toughened with the addition of Yttria, Hafnia and Alumina. All were formed from micron-scale crystalline grains. The Gibson and Dollar store blades contained very similar concentrations of additives (suggesting a common manufacturing source), while the Kyocera contained about half the amount of of Yttria of the other two. Comparison of the grain structure (from just a single spot and sample of each) displayed subtle differences. (This is clearly not intended to be a comprehensive or systematic comparison). The Kyocera ceramic was the finest grained with obvious grain sub-structure. The Gibson ceramic had the most voids, particularly at the triple-point intersections of the crystals. The Dollar Store blade had similar grain dimensions, but also contained a small number of aluminum oxide grains (dark in the images). There is no obvious deficiency in the blade material to warrant the rather ominous warning on the Dollar Store blade packaging “Hand wash only. Wash and dry immediately. Do not Soak.” However, the presence of aluminum oxide grains may suggest the material did not meet quality control standards and also explain how it ended up in a dollar store. Whether these observed differences will correlate to variation in performance and/or “sharpness” longevity is beyond the scope of this investigation. I would expect that there are differences in the “toughness” of the various blades – for example, how easily they will break if bent too far or dropped on a hard floor. Anecdotally, I did not observe any obvious difference in the cutting or sharpening performance of the three blade samples.

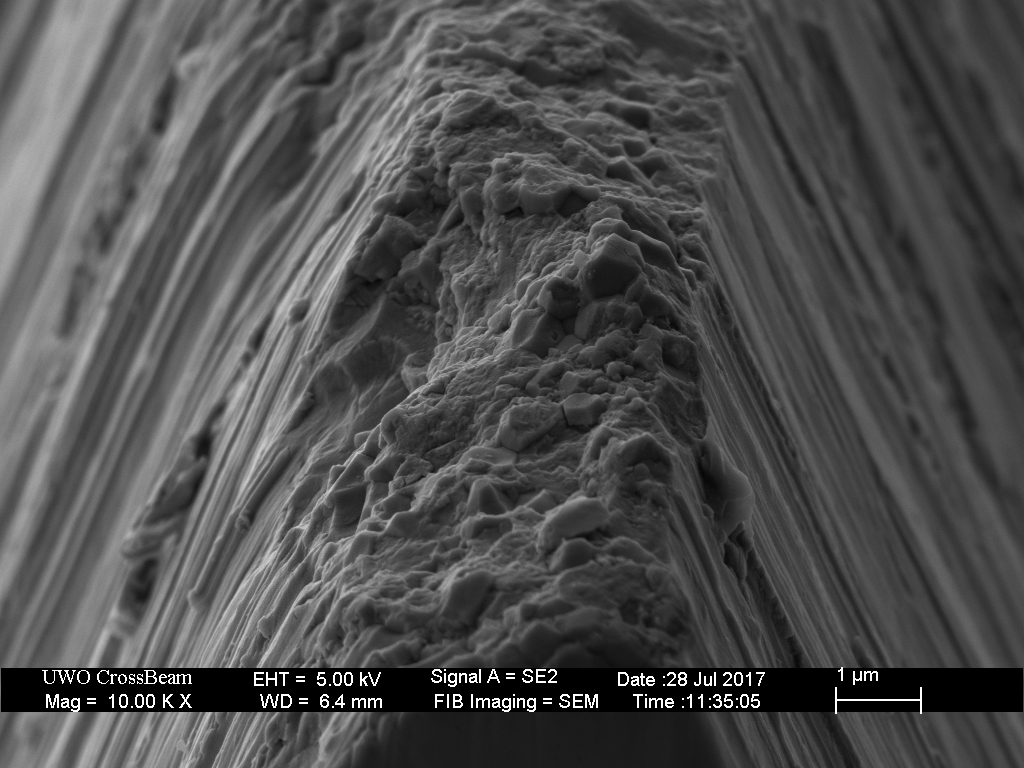

Ceramic knives are purportedly difficult to sharpen, and in the following images I document a few attempts with conventional hand sharpening to help understand the reason for this reputation.

In the first example, the blade was sharpened with a DMT extra fine (1200 grit) diamond plate. Although the blade material was efficiently ground away, a keen apex never formed. Instead, the apex continually broke away leaving a 3-4 micron wide ‘flat.’

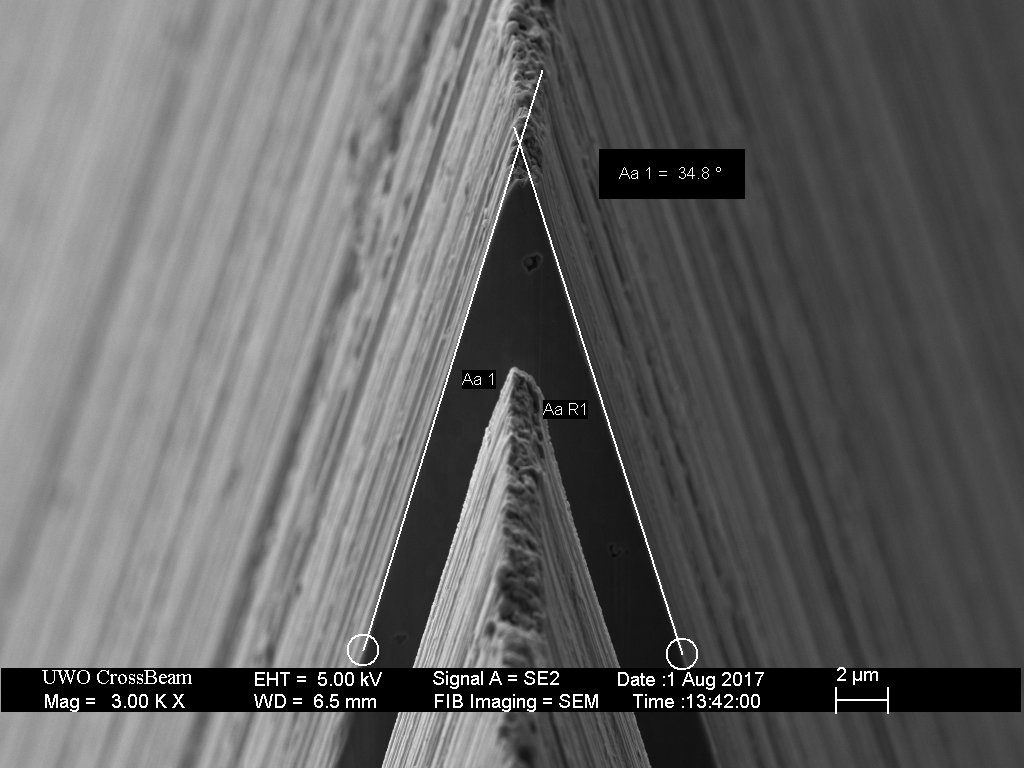

In the second example, I sharpened a Kyocera vegetable peeler blade with a very fine hone, a 16k Shapton Glass stone. This was much more effective than the Diamond plate above.

Traditional steeling with a ceramic rod is a disaster, actually reducing the keenness of blade. Steeling relies on the high local pressure generated from the small contact area of a rod approaching at an angle greater than the bevel angle. This high lateral pressure simply breaks away the apex faster than a microbevel is formed.

The following images demonstrate that stropping is a viable approach. This result is not surprising, since stropping produces micro-convexity with modest lateral pressure at the apex.

Noting that the grain structure is not evident in the side view of the ground bevel, it is apparent that zirconia is abraded by the aluminum oxide in the 2k stone without “tearing out” individual zirconia grains. However, at the apex, the blade consistently separates along grain boundaries resulting in sub-micron roughness.

Fine grit hones and strops are effective at thinning the ceramic apex because they produce less lateral force than do coarse hones. Steeling (micro-beveling) is ineffective because of the large lateral pressure that is exerted on the near-apex. The challenge in sharpening these blades with traditional (coarse) abrasives is that the apex continually breaks off as the bevel is ground, and a keen apex never forms. The burr that typically forms at the apex of a steel blade during sharpening is the result of flexibility of that thin metal. Since ceramic blades have no flexibility, a burr will not form.

The SEM observations show that the perceived sharpness of Ceramic knives is not a result of geometrical “keenness” but instead derives from the texture of the underlying microstructure. This texture is easily produced in the apex due to the susceptibility of the material to micro-chipping and the lack of flexibility. Without malleability, there is no smooth blunting or mushrooming as we normally see with steel blades; instead the two shoulders of the apex continue to maintain sub-micron level keenness as the blade wears. The fact that the blade wears by separation at the boundaries of the sub-micron sized ceramic grains ensures that the apex surface maintains an abrasive texture as it wears. Additionally, the abrupt geometry of the shoulders can be maintained as the apex flat broadens. With use, the continual micro-chipping will expose a fresh (flat but rough) apex with relatively keen shoulders. In this way the blade maintains a perceived sharpness. As a result, the blade can continue to perform acceptably, even as the blade wears. This explains the observation that these knives “stay sharp” for an extended period.

26 responses to “Ceramic Blades”

About time! Going through withdrawals here. *Wink wink* lol. Out of curiosity, when you tried the diamond plate did you try both edge leading and edge trailing? And you mention that the Shapton stones cut the ceramic – but is this basically only going to be viable for finishing? Can they cut well enough to set a bevel? I have sharpened a few ceramic blades finishing up edge trailing with diamond (DMT EEF to finish and some light stropping with loaded leather) and this worked great – much keener than factory edges and able to push cut paper easily as well.

LikeLiked by 1 person

I didn’t observe any difference between edge trailing and edge leading, but I only tried this on a couple of hones. There are a few ways to approach this, but fine abrasive followed by stropping or buffing looks like the best bet. I may do a part 2 to this at some point.

LikeLiked by 1 person

Very Cool! I’m not quite sure what I’m looking at on the peeler pic. I know what I’m about to ask isn’t the focus of the study but what would you recommend as a sharpening protocol? Looks like the 16K Shapton glass finished with the Denim/Mothers strop.

LikeLiked by 1 person

The peeler initially has a single bevel (on the left) and I sharpen it with the 16k at the same angle on the left, and create a second bevel on the right. This looks like a good approach for a micro-bevel where we don’t need to remove too much material.

LikeLiked by 1 person

Missed seeing your posts Todd, great to see this! Thanks for the research and analysis!

I am curious if a ceramic blade could be sharpened on a belt… maybe when you get that Viel you can experiment around a bit 😉

LikeLiked by 2 people

I’m expecting that a very fine belt will work quite well for these type of knives. Definitely would want dust extraction though.

LikeLiked by 1 person

Thank you for sharing, very much appreciated. Just knowing that some common stones can touch up a ceramic edge is useful and the photo of the result with stropping speaks volumes. A very useful investigation. Again thanks.

LikeLike

Excellent post Todd! Excited to see the fresh content again.

LikeLike

Todd,

Thank you ever so much for sharing this most valuable information; Haven’t seen the like of it anywhere else!

A suggestion for possible future research: Surface conditioning and cutting action of fused ceramic abrasive stones as represented by Spyderco.

LikeLike

I recently purchased a 204mf, and may include some results from that in an article on steeling that I am working on.

LikeLiked by 1 person

Todd,

Eagerly looking forward to whatever you publish.

Cheers

John

LikeLike

Looking forward to reading your article on steeling. Would it be possible to determine a ‘perfect angle’ for a set bevel? In other words, exactly how much wider than the bevel for the best edge. Perhaps you know? Also pressure? Light is better but is there a perfect amount of pressure?

I know theres a budle of variables, bevel angle, knife hardness and what hone is it ceramic, diamond or is it a f dick combi style steel.

Just thought I would throw something to think about.

Keep up the amazing work, truly remarkable information you have here.

LikeLike

I’m not sure how we could determine the “best” angle since it depends on what we are cutting.

My personal preference is sharpen knives at 30 degrees (inclusive). Apex angles below about 25 degrees seem to weak to be of any practical use. From there, I will use micro-convexity or a micro-bevel to increase the strength/stability of the apex.

For steeling, it is critical to use an angle at least 10 degrees larger than the the sharpening angle to minimize the contact area. Pressure in sharpening/honing is mostly determined by the contact area rather than the force you apply. I will try to make this more clear in the steeling articles.

LikeLiked by 1 person

Aloha Todd, thanks for sharing this amazing imagery, its thanks to you I bought my metallurgical microscope, still didnt satisfy the itch, but made me feel better for trying.

Question: Since mothers mag polish is inexpensive and seems to work good, did you observe the micron grit size and variance? Apologies if you posted and I missed that detail.

Thanks again for doing these amazing studies!

LikeLike

Cliff, I looked at a variety of metal polishes and they were all fairly similar -mostly micron scale with a few 10-20 micron particles. So long as you use a substrate that can absorb the large particles, they all seem to behave comparably.

LikeLike

Arrived here after searching for a steel vs obsidian keenness SEM image comparison. Given how good the rest of your comparisons are I think you could do a better job than any I have yet found.

I only use a basic 1000/6000 King stone for my knife honing, so am hardly your target audience I’d wager. I don’t even own a strop! Appreciated your work though.

LikeLike

So I was wondering if you knew how the leather works during stropping, not the effect on the blade. I want to know this because I’m wondering what characteristics I want from my leather in my strops. I am researching a lot about sharpening and I am trying to get into doing my own testing but before I test anything, I want to make sure it hasn’t been done before and the answer is somewhere to be found.

LikeLike

I’ve never found any published research on the topic. Leather is not easily imaged with SEM, but the few samples I’ve analyzed had fairly similar surfaces. There are a variety of options for tanning, conditioning and compression – but that’s not within my areas of expertise.

LikeLike

Thanks for the reply Todd,

Yeah Im still learning. I think I know what you mean contact area vs force in other words less pressure on coarse and slightly more on fine steel? Hmm I’ll just wait till you’ve finished your steeling articles lol.

LikeLike

Hi Todd!

I really like your articles! Could you one day show the difference between strokes parallel to the edge, instead of edge trailing and edge leading? Since edge leading causes micro-chipping, and edge trailing can cause burr, I was wondering if parallel to the edge could be better, or if it would simply cause large session of the apex to chip.

LikeLike

From the few times I’ve looked at it, edge parallel seems to be equivalent to edge trailing. One potentially downside is that parallel strokes can often create horizontal scratches near the apex that weaken the edge.

LikeLike

LOL! This is exactly what I found and talked about in my X stroke series of videos. Validation is nice. Thank you.

LikeLike

Great to see evidence based investigation. I have read recommendations to “strop” on a smooth and relatively hard surface, typically wood, instead of leather and using an appropriate compound (diamond paste??) If I read your work correctly you had the best results with stropping. Have you tried using a wood or other surface for stropping?

LikeLike

I made an attempt at sharpening ceramic knives using wet/dry sandpaper a few years ago but without success (and subsequently got rid of the ceramic knives). This article gives me new hope and as I have since acquired two King stones (#1000 and #6000) maybe I’ll find some old ceramic knives and try again. Do you think these King stones will be as effective as your Shapton Glass stones?

When you stropped the peeler blade, how many laps were necessary? I’m thinking that if stropping is going to be the major factor in getting a good edge on ceramic knives then it might be worthwhile making a powered stropping disk out of some MDF with leather glued around the circumference (loaded with CrOx) and mounted on a small bench grinder.

LikeLike

You don’t want to sharpen ceramic with anything that produces mud/slurry, so definitely not the King stones.

LikeLike

I got a black Kyocera blade a year ago and found it to be far more difficult to sharpen than the white Kyocera ceramic. Everything I did caused extreme chipping using resin bond diamond stones. I ended up trying leather as the “bond” and added diamond powder to abrade the ceramic, from 20 micron to 1 micron reducing the size by 50% for each step. It was a total game-changer, all of a sudden microchipping was not much of an issue. Anyway, if you do a part 2 try to add a black Kyocera blade as the ceramic is quite different than their white, far more challenging. Interestingly, it doesn’t seem to be as prone to chipping in use.

LikeLike