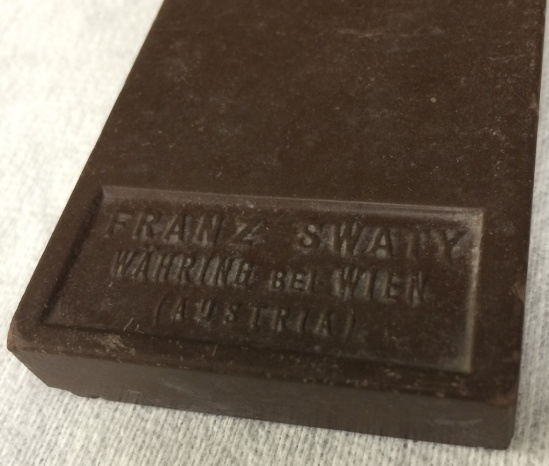

Before the technology existed to produce finely graded sub-micron abrasives with narrow particle size distributions, the ubiquitous barber hone was commonly used to maintain straight razors.

In comparison to modern synthetic hones, these vintage barber hones seem relatively fine. One might wonder if some undocumented process existed to produce ultra-fine grit hones a century ago. A quick analysis with an electron microscope reveals that these hones are not fine by our modern standards. Abrasive particles are tens of microns in size, many in the region of 30 microns, corresponding to 600 grit.

Although the abrasive particles are relatively coarse, a barber hone is typically “conditioned” to smooth or glaze the hone to a point where the grit is nearly ineffective.

The image above shows a grit particle in the “conditioned” state – smooth and level with the surface of the clay binder.

28 responses to “The Barber Hone”

Do i understand it right, that the abrasive particles are quite coarse, but due the prepping of the stone the surface is also smoothed out. So moving the razor over the surface we only partly hit the edge on several points of the bevel where the abrasives are stuck into the binder ?

Might this result in the often named micro serrated look ?

Regards

LikeLiked by 1 person

Yes, essentially “conditioning” of the stone for razor honing reduces the exposure of the grit particles so that blade only makes glancing collisions. This will minimize the occurrence of micro-chipping and thereby enhance keenness.

A similar effect occurs with other types of hones. If we want to maximize abrasion we would “recondition” by roughing up the surface. If we want to maximize keenness, we would “condition” by smoothing the surface. This is also the principle behind creating a shaving edge with a coarse diamond plate. This is all assuming edge-leading honing strokes.

LikeLiked by 2 people

Thanks, i think it comparable to dress up Arkansas Stones….you can dress one side quite fine with a 600/800WD paper and one side with a 200 or 400WD, depending on the dressing you get different honing results…

This also works with many types of Quartzite stones, the finer the stones are lapped, the finer is the result…

LikeLike

So based upon the comment above… how do you condition the surface of the barber hone or the diamond plate? After my new dmt 325 plate gets broken in I think I will take up the ‘challenge’ to hone a razor on it and see how it shaves. Ever since you have said that my curiosity has been peaked!

LikeLike

What we call “broken in” is somewhat subjective. For example, someone honing a straight razor with an Arkansas stone will want the surface smooth as glass, while someone trying to sharpen a knife may might call that stone “glazed” and ineffective.

I like to use the analogy of a hone as a “bed of nails.” It doesn’t matter how long the nails are – only how densely they are packed and how sharp the tips are. The force is spread uniformly over many nails resulting in a modest pressure at each point. If one nail sticks up above the others, the pressure is very high at that one nail. For a diamond plate, we want to even out the tips to the same level – otherwise the one high point will produce very high pressure and consequently a deep scratch. I have used a screwdriver shank to knock down the high points (those diamonds also receive very high pressure).

LikeLike

Gotcha. You also may want to try lapping some glass on it… seemed to really “break in” my old DMT =) it got really smooth.

Great explanations thanks!

LikeLike

It appears that much of the damage was caused by loose diamonds, so it makes sense that the surface we use for break-in plays a role. For example a flat piece of steel may trap the loose diamonds while a screwdriver shank may allow them to be flushed away.

LikeLike

This seems to support my recent habit of using a polished rustenburg black granite slab after my 1600 grit stone. I am too broke to buy the stones i want – i am sure stones or lapping plates would be quicker and probably better too, before i do compound loaded strop… It does take long… and the edge is quite irritating to the skin as is…

LikeLike

Interesting. Same concept as Tormek uses with their stone grader.

LikeLike

Interesting, to the best of my knowledge the abrasives used in barber hones were graded 300F,400F,600F 1200F. The proper interpretation of this is the coarsest abrasive size of 1200F is 1200 and FINER ! Since I purchased the recipes from the American Hone Co. I do know what grade of abrasives were used. There was not just one size of grain in each of the grit rating , it varied . It was later that the ANSI standards were developed where a abrasive particle size distribution curve was developed.

Regarding the “conditioning”. All of the hones were lapped at AHC and some were also buffed or rubbed.

LikeLike

Thanks Randy, I’ve not seen that information before. I’m sure the people who claim their barber hones are 6k, 8k or 10k+ would like to know this (not).

This article was intended as another point of evidence that the idea of “grit” and assigning grit to hones is foolish. As I showed in the Abrasion vs Grit article, large particles don’t do much if they are smooth or there isn’t pressure far beyond what we use for straight razors.

LikeLike

Especially considering the mix of industrial grit size standards and how few people bother to state which standard they are referencing. Japanese 1200 has particles similar to an ansi 800(if memory serves). Combined with some rather out dated grading methods used to form said standards leading to non-linear numbering systems, and by non-linear I don’t mean exponential, I mean arbitrary, with big steps then small steps then back to big steps as you progress from coarse to fine; and variation with end use eg coated-paper, sintered wheels, loose grits all have different micron curves for the same grit number.

In short: Even if binders, steels, and technique are controlled its still not apples to apples.

LikeLike

This is really fascinating information. Just the other day I was spreading the “Jnat slurry breaks down” fallacy and now I feel like a fool for spreading propaganda. So what gets a razor sharp if it’s not particle size alone? I guess pressure plays a large role. Are the whetstone manufacturers scamming us with all these various stones from 220-30K?

LikeLike

Hi Todd,

Any suggestions as how to “condition” a black surgical Arkansas for sharpening razors?

Cheers

John

LikeLike

I would try a buffer wheel after lapping it flat.

LikeLike

Hi Todd and Randolph,

Thank you both for your suggestions.

Cheers

John

LikeLike

My apologies, I had mis-read your post. I thought you were asking about lapping.

LikeLike

The hard Arkansas stones will ruin a diamond plate and aluminum oxide sandpaper is a waste of money. So far the best idea is to use loose abrasive grain silicon oxide (SIC), 320 grit on a flat tile. Some oil will help keep it in place. Then condition with the shank of a screwdriver or similar tool.

LikeLike

Todd,

Just tried your suggestion of buffing the stone and obtained very good results, akin to lapping with a ceramic stone and 0.25u diamond, but much less effort and quicker. Tomorrow I will try various fine abrasives. Today I buffed on a sisal wheel charged with grey compound (coarse).

Cheers

John

LikeLike

Randolph,

That;s OK. I lapped the stone on float glass with silicone carbide powder and in the finals stages against a ceramic stone and diamond paste.

Cheers

John.

LikeLike

Todd,

Today I buffed the black surgical Arkansas on a hard felt wheel impregnated with 0.1u diamond suspension.

The scratch pattern did not improve over that obtained with a sisal wheel and coarse buffing paste. I estimate that the resultant scratch pattern to be similar to that of a #8K Shapton and nowhere as fine as my ancient Thuringian stone.

Best results so far were obtained with a Spyderco UF lapped and conditioned. The scratch ( and burnish?) pattern well exceeds that of a #16K Shapton.

Cheers

John

LikeLike

Does it work well for sharpening razors ? Does it give a smooth shave?

LikeLike

Dorin,

Which stone are you referring to?

Cheers

John

LikeLike

I am referring to the barber hone in general. How do we reconcile the fact that it has low grit compared to what is used today for sharpening razors yet it was the tool back in the day the straight was the only way to shave. That is why I am curios how does it compare to the modern method of using high grit stones. I find that having a stone or maybe two for sharpening razors should be the ideal way, in the end this is a simple activity and making it so costly and time consuming doesn’t apeal to me. It is very interesting to follow the resarch but I wonder if we are not trying to reinvent the wheel . Since a diamond plate DMT325 gives a comfortable shave maybe low grit stones are something to be explored more.

LikeLike

The short answer is that “grit” is not a very useful concept in sharpening.

The long answer is something I have been explaining for the past few years in the various entries in this blog.

In my limited experience with barber hones, I haven’t found anything that would lead me to recommend one. In my opinion, the prices they currently command are based on collectability and nostalgia, not performance.

LikeLike

I don’t know about you guys but all this race for high grit stones makes me nuts. I just tried lapping film and I probably raised a burr because it gave me horibble shave. On optical magnification the edge looked very good, but probably was not. I decided to stick to Todd’s method but I will give coticule a try in the future. I just wish there was a synthetic alternative to coticule and wonder if barber hone is it.

LikeLike

In general, lapping film will produce a foil edge, especially diamond or PSA-backed film. The Al2O3 film is better option, but it must be followed by a pasted strop to properly form the apex.

At some point, you need to decide whether you want to make honing a hobby, or just get it done efficiently and repeatably so that you can enjoy the vastly superior shave that a straight razor provides.

LikeLiked by 1 person

I have found that with a coticule when finishing, do it under running water with almost no pressure you can get a great shaving edge. Not all Coti’s are the same as not all razors are the same

LikeLike