The word sharpness generally refers to observed cutting performance. In the absence of the quantitative microscopic measurements used in the experiments described here, macroscopic observations allow relative comparisons of sharpness. The ability to cut hair is a common blade test. Although the test can be performed in several ways with varying interpretations of the result, the premise of such tests is that the blade must be keen enough to penetrate the hard, thin cuticle sheath and sharp enough to sever the hair with minimal force. The Hanging Hair Test (HHT) is eloquently described by my friend Bart Torfs on his website coticule.be where he discusses the interpretation and quantification of the HHT test.

The HHT is a two step process; first, catching and penetrating the hard cuticle shell and second, completing the cut. “Catching” only involves the last micron of the edge and the keenness or width of the apex. Cutting or force to cut will involve not only keenness but bevel angle (thickness behind the edge), and friction from smoothness/polish/coating of the bevel over no more than the next 100 microns (diameter of the hair). Since the hair is held only at one end, it can bend away from the blade if the force-to-cut is greater than that required to deflect the hair. Although the physics involved is complex, the test does provide a relatively simple determination of whether the edge is at or below the required keenness threshold. Unfortunately, if the apex is just 50nm (0.05 microns) thicker than the threshold, it will not pass the test, although the blade is still very sharp by almost any standard.

My own experiments have shown that an edge width of approximately 100nm is required for shaving. This corresponds to an edge radius of 50nm, consistent with the measurements found in Gillette razor blade patents indicating a manufacturing target of 200-300 Angstroms (20-30nm) for the edge radius. Unfortunately, even the highest grit synthetic stones, when used with edge leading strokes, only just reach this level of keenness. Very light strokes, or edge tailing strokes can bring the apex width down the few tens of nanometeres required; however, a triangular bevel with a 16 degree included angle is typically too weak to survive shaving a normal-to-heavy beard. Abrading the apex by stropping will micro-convex and bring the keenness past the threshold while simultaneously making the apex more robust.

There is a commonly repeated myth that a hand honed and stropped blade cannot be as “sharp” as a factory sharpened razor blade. The images below prove this statement to be false. The straight razor shown is both keener and sharper (thinner behind the edge) than the Feather DE blade for the first 50 microns from the apex.

There is a common misconception that finer grit honing and stropping correlates with sharper and keener edges. As a example, blade sharpness is sometimes (mis)described by the effective grit rating with the belief that a “12k edge” is keener than a “10k edge”. The difference between edge-leading and edge-trailing strokes, shown in the pasted strop part 1, and the results from coarse diamond plates in the diamond plate progression, have already shown how misleading this concept is.

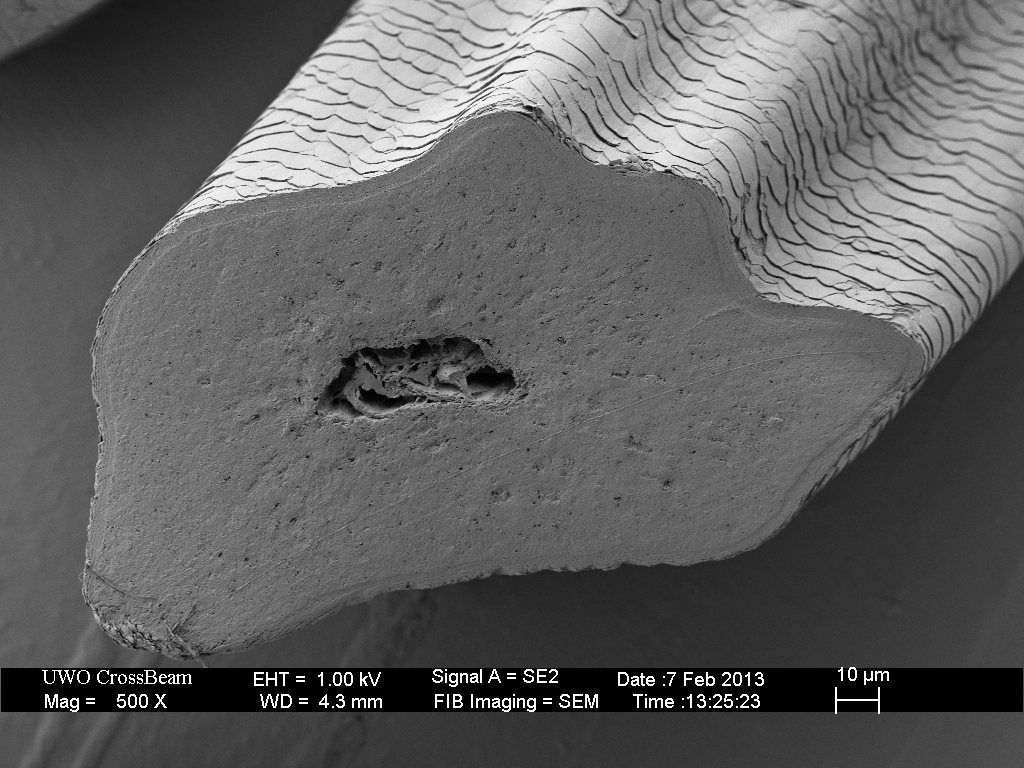

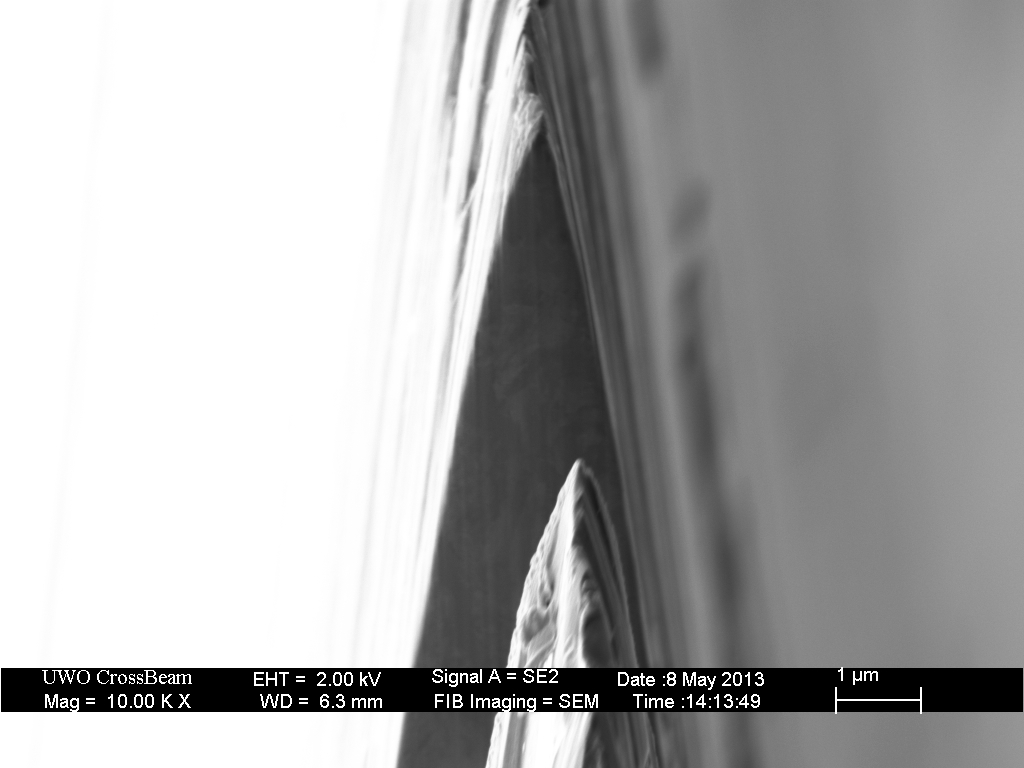

The images below are from a straight razor honed on a Belgian Coticule, without stropping. Analysis of this particular stone reveals the abrasive (Spessartine garnet) is between 5 and 10 microns in diameter, equivalent to the grit in a Shapton 2k hone. Unlike the edge produced by a Shapton 2k stone, the Coticule-honed edge is easily keen enough to shave. Avoiding generalizations about Belgian Coticules, the results clearly show that grit size does not determine keenness. In this particular case, the apex has been micro-convexed by the honing surface, in a similar fashion to that observed for coarse diamond plates, resulting in what I have personally observed to be a nearly perfect shaving blade geometry.

In summary, “sharpness” must be measured by a method consistent with the intended purpose; it is not predicted by the size of the abrasive grit applied.

24 responses to “Sharp and Keen part 2”

What I find the most interesting in this post is to be able to get an idea of the relative sizes of the hair and the blade edge. There are no photos of the razor blade and the hair together, but from the magnification on each photo I can imagine. When you give a numerical value for an edge width or radius is means very little to me because I have no scale by which to visualise microns, nano metres or Angstroms. Seeing the cross section of a hair brings things into perspective.

LikeLike

It is challenging to convey a sense of the pertinent length scales. I chose the set of whisker images particularly for this purpose. I’m glad this was helpful to you.

LikeLike

By the way, you have a very clear writing style that is easy to read. Good use of grammar, vocab and spelling. It mighe seem trivial but it makes a change from a lot of what is written on the internet.

LikeLiked by 1 person

Absolutely. Clear mind, precise words. A delight.

LikeLike

Another excellent article! I think I’ve learned more here than from the seminal sharpening books everyone recommends to beginners.

LikeLike

I’m curious as to why the Belgian Coticule leaves a smooth shave-able edge but it looks like crap when under the microscope?

LikeLike

I assume you are referring to the hazy “sand-blasted” finish of the bevel. This is caused by garnets rolling between the stone and blade; the corners of the garnet create “dents” in the metal resulting in diffuse reflection. The geometry of the apex, which is what determines the “shave-ability” is independent of the bevel finish. As one example, edge-leading and edge-trailing strokes on a synthetic hone create identical bevel finishes, but completely different apex geometries.

LikeLike

Can you dumb that down a bit for me please, I have a coticule and never questioned why it works but these articles are so very interesting I am starting to wonder now.

LikeLike

I think OP was asking about apparent “toothiness” of coticule edge in this plan view. I’ve been wanting to ask same question based on photo micro graphs of coticule edge in other threads. I can see the micro convexity you refer to, but coticule edge appears far less refined and keen than the edges micro conveyed on hanging denim and .25 micron diamond strop. Why does the coticule edge shave so well? Is the coticule edge in this picture ready to shave, or would the edge need to be made more linear with stropping?

LikeLike

I’ve not talked much about the non-uniformity of the blade (I won’t use the word ‘toothy’ since it is very misleading).

The short answer is that uniformity is not necessary for shaving. We need ‘most’ of the apex width to be less than 100nm (ideally 50nm) but it seems that the imperfections don’t reduce shaving efficacy.

LikeLike

“the results clearly show that grit size does not determine keenness.”

I don’t think this is a statement that can be made across the board. For example, in your post “The Honing Progression” you show how keenness does indeed increase with an increase in grit. Conversely you showed in “The Diamond Plate Progression” where keenness does not increase but decreases w/ increase in grit.

So from what I have seen so far it seems to depend on several factors:

– the stone/grit/substrate

– the condition of the stone

– the manner in which the stone is used (edge trailing vs. edge leading, pressure used, etc)

It would seem that much more research is needed, as you also conclude =)

Thanks for all the work you put into this so others that don’t have access to this equipment can learn!

LikeLike

To clarify, grit size is one factor, and with all else equal (if that is possible) keenness should increase with grit.

LikeLike

I think that you and I may have had a little back and forth on another forum Todd. I followed your link from that forum to this page. Absolutely spectacular photographs! Without a doubt the best and most informative I have ever seen. My hat is off to you and your work.

LikeLike

Fantastic blog, thanks for sharing all this stuff!

Have you tried less than 10 laps in the latigo strop to see how is the apex before the foil edge burr appers?

LikeLike

As I showed with 3 laps on balsa strop, these effects occur rapidly, and attempts to avoid the foil-burr with fewer and/or lighter laps were not successful (with this particular strop).

A foil-edge can be usually be avoided by either using a harder strop instead (eg balsa) or, more reliably, by pre-convexing the edge with a coarse paste on fabric (eg metal polish on hanging denim) prior to stropping the diamond on latigo.

LikeLike

What was the honing and stropping progression for that razor blade?

Very interesting work and great post.

LikeLike

That particular blade had an unnecessarily complex progression. Similar results can be achieved with a synthetic progression to 8k, followed by aluminum oxide metal polish on hanging denim to produce micro-convexity, and finished with 0.25 micron diamond on hanging leather.

LikeLike

Hello, do you find any difference between: Feather new hi stainless steel “yellow pack” versus Feather hi stainless “black pack”? It would be nice to see SEM image comparison.

Thanks for your work.

LikeLike

I recall comparing them many years ago, and couldn’t see any difference.

LikeLike

very interesting stuff…i am struck by the strong parallels of the micro geometry in the photos with the macro geometry of a cross section of classical tanto or nihonto, very similar! beautiful.

LikeLike

Great page, many thanks for sharing with us!

I would be interested in how a prepared mustache whisker would look like under this high magnification.

Many thanks

Philipp

LikeLike

Have you tried Belgian Blue whetstone? Some say it works just like a corticule, and others say it does not. Does the BBW and the corticule actually have similar results?

LikeLike

corticule->coticule. I used a Google Translator and got a word error.

LikeLike

Hi ScienceOfSharp,

Beautiful images and really interesting discussion. Would it be possible to include the first 3 images in my university thesis? I will of course credit the images appropriately.

Ella

LikeLike