In The Honing Progression entry, an example of apex geometry refinement during honing with Shapton glass stones was presented. A slow, but linear improvement in sharpness and keenness was observed, consistent with the intuitive view that reducing abrasive size (increasing grit) leads to a sharper, keener and more linear edge, along with a more polished bevel. In the current discussion, examples taken from honing on diamond plates will show that the reality can be more complex.

There are two primary differences between diamond plates and conventional water stones; the diamond plate grit is more firmly bonded, and can exert a greater lateral force without dislodging, and second, unlike a water stone, fresh grit particles are not being continuously exposed with use on the diamond plate surface. It must be anticipated that the effect of a particular diamond hone will depend on the existing condition of the surface; whether the stone is broken-in, worn, glazed, etc. For this reason, the examples here cannot be generalized to all diamond hones.

A set of 4 diamond plates were used for this experiment; DMT coarse (325), fine (600), extra-fine (1200) and extra-extra-fine (8000). The four plates were in good condition, and were “broken-in,” all having been used for more than one hour polishing steel. A carbon steel razor with spine-apex angle of 16.5 degrees (inclusive) was honed edge-leading with pressure in the range normally used for honing straight razors; beginning with a force-equivalent of a few hundred grams, reducing to near “weight of the blade” pressure at each stage. The observed results were confirmed repeatable, indicating relative insensitivity to variations in pressure, stroke type and number.

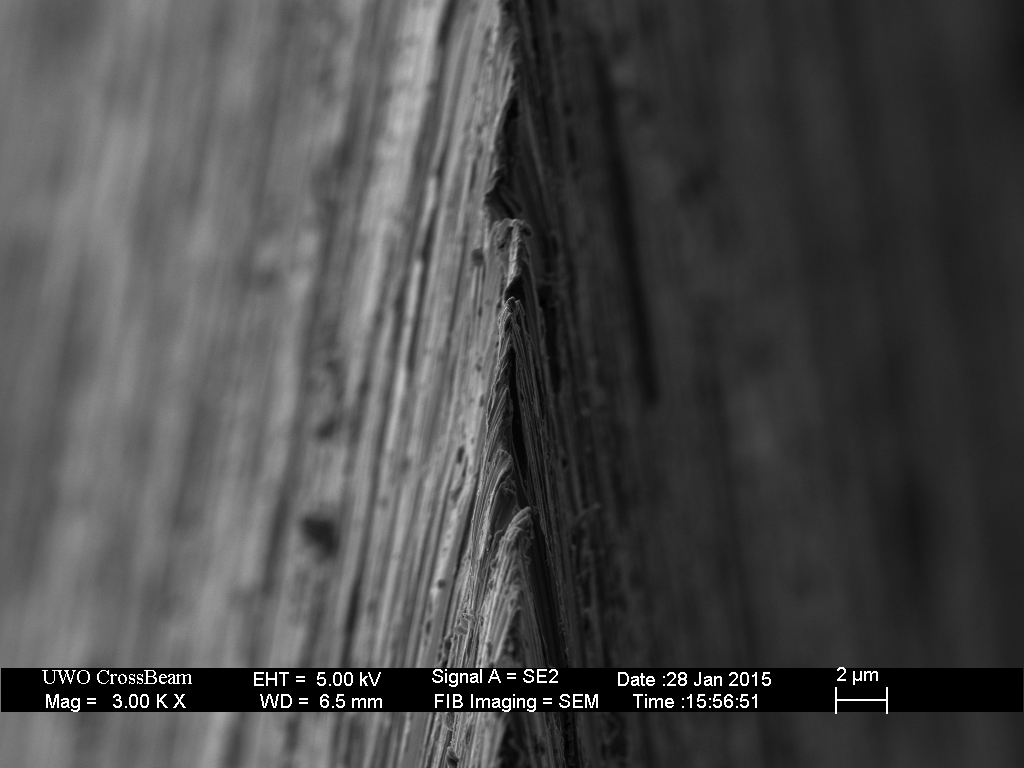

Comparing side view images, all at 5000x magnification, shows that the roughness of the bevel actually increases with grit, rather than decreases as was observed with the Shapton water stones. The scratches are wider and shallower on the lowest grit hones, becoming progressively deeper with increasing grit.

Imaging edge-on also shows the counter-intuitive result of decreasing edge keenness and uniformity with increasing grit.

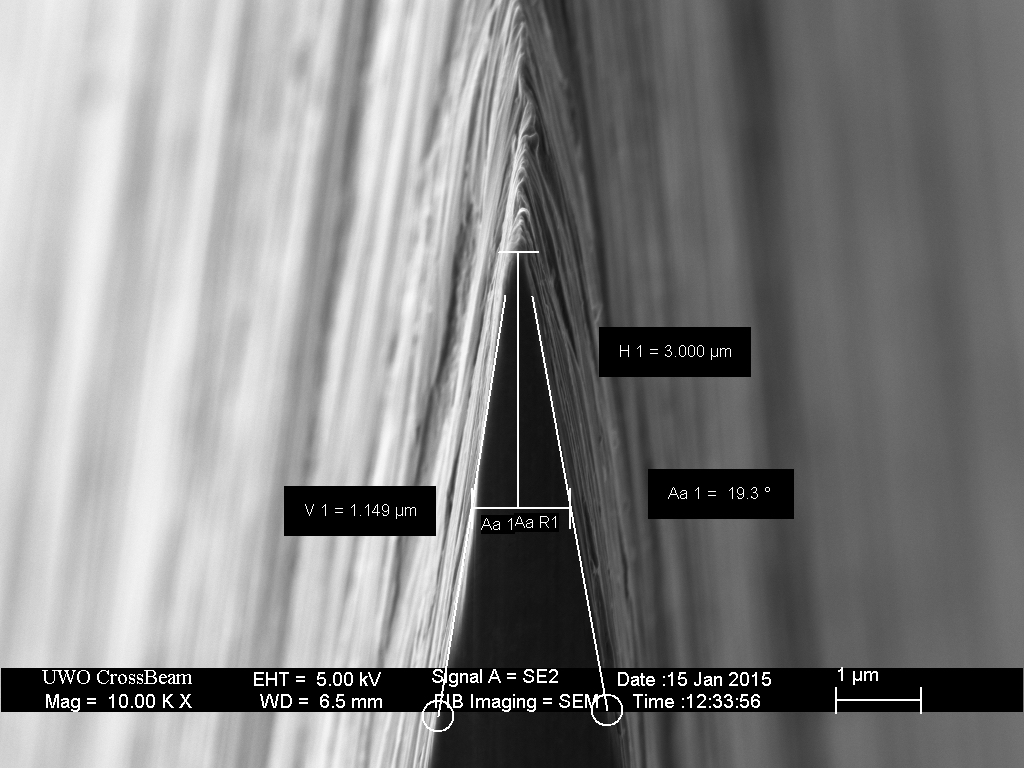

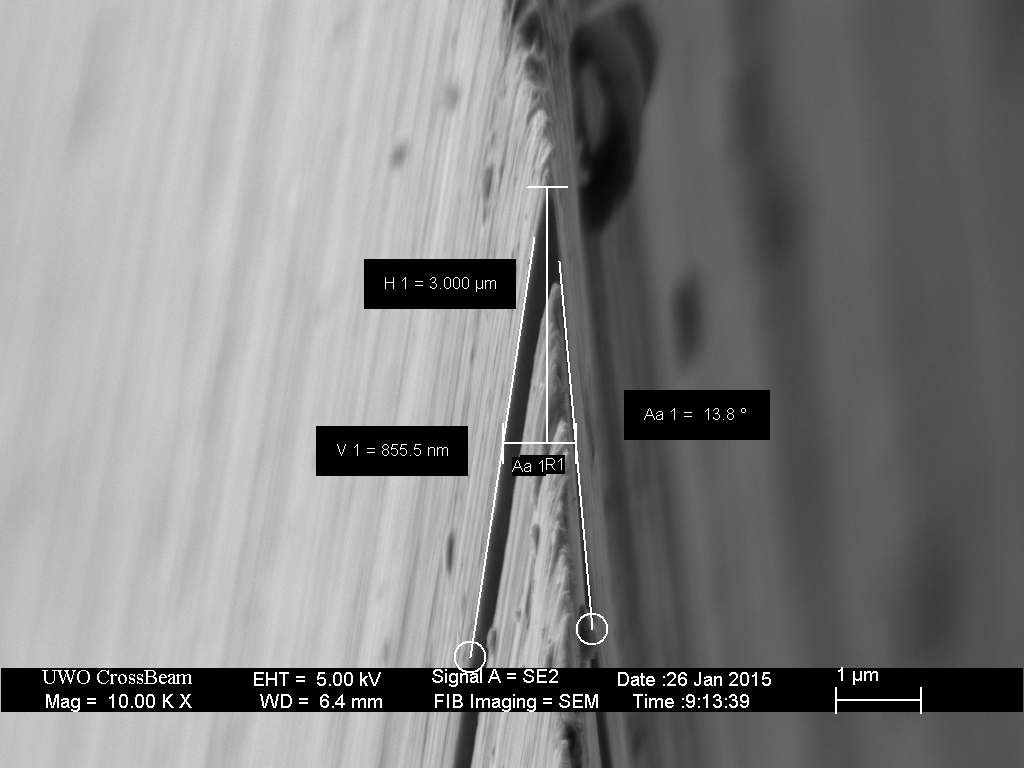

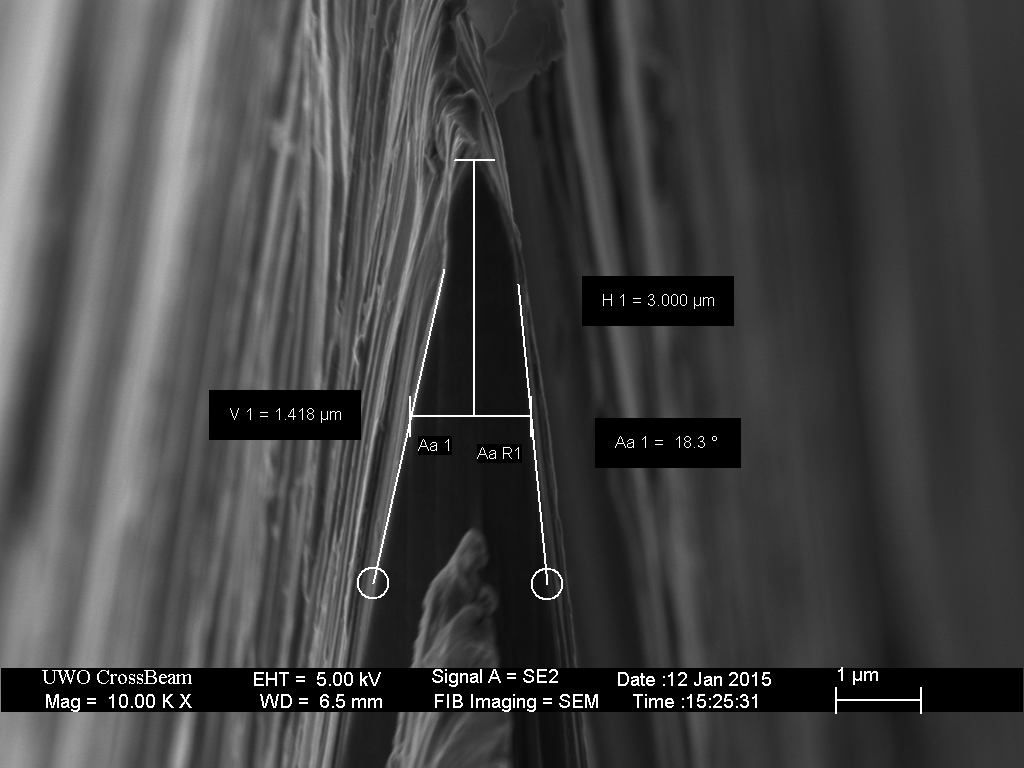

The edges were also cross-sectioned and imaged to determine the near-apex bevel angle. 3 of the 4 edges display similar micro-convexity, with the 600DMT edge being a foil-edge burr.

The reader could be forgiven for concluding that these results make no sense, that the author has no honing skill, that these particular plates were defective, that razors are completely different from knives, or any other dismissive explanation. Often, results that contradict our intuitive expectations are a key to identifying and improving our deficient understanding. Certainly it would not be prudent to generalize these results and a full understanding of these observations will require further experimentation; however, a few insightful comments can be made at this time.

In order to form a scratch, sufficient pressure must be exerted by the particle (or a corner of the particle) to exceed the yield-strength of the material. Since pressure is inversely proportional to contact area, a larger smoother particle will require a greater force to scratch than a smaller or more irregular particle. The observed scratch profiles indicate that the Coarse(325) and Fine(600) diamonds are too large (and smooth) to individually penetrate the steel (at the force applied), instead only the asperities on the surfaces of the diamonds abrade the bevel. This is not a burnishing effect; metal is being removed in these examples. The Extra Fine(1200) and Extra Extra Fine(8000) diamonds are small enough or sharp enough to penetrate and form discrete scratches. The smaller surface area of those contact points results in a higher pressure (force/area) and therefore greater penetration and deeper scratches. In the pasted strop-part 3, it is shown that the transition from a triangular profile to micro-convexity can include the formation of a foil edge. For this reason, the observed foil-burr in the 600 grit example is not inconsistent with the apex profiles observed after the other three grits.

It is surprising to observe micro-convexity on an blade honed on an incompressible, flat surface (without slurry). Further, the amount of micro-convexity does not vary with grit size; we observe nearly the same near-apex profile after the 325 as we do at the higher grits. One possible explanation can be found in the fact that plastic deformation occurs at the apex during honing. The amount of plastic deformation is a function of the steel and bevel angle, not of the of the grit size on the honing substrate. A likely mechanism for this result is shown schematically in the images that follow.

When the bevel is convex, the apex rides above the surface and is somewhat “protected” from direct collision with abrasive. This can enable the production of an edge much keener than might be anticipated for a particular grit size.

Almost any measure of sharpness or keenness of these four blades would show a reduction in cutting efficiency with refinement on higher grit plates. The expectation that low grit edges are “toothier” may lead someone to believe that a toothy edge is superior in some applications. However, the micrographs show no evidence of “toothyness” in the 325 or 600 grit edges. In fact, those edges appear highly refined. Whether the 1200 and 8000 grit edges could be qualified as “toothy” is up for discussion. Certainly the toothy-blade myth is something to be investigated further.

The 325 DMT finished edge (shown below) has the characteristics of an ideal straight razor shaving edge. Three different straight razors were honed on this DMT plate and confirmed to provide an excellent straight razor shave, as would be expected from the highly refined apex profile. A remarkable result, but unlikely to start a trend among straight razor users to finish their honing with a DMT 325 plate…

For comparison, a blade was honed on an Atoma 400 diamond plate. This plate was used exclusively for lapping waterstones, resulting in a rougher, less polished surface. Images of the blade display a scratch pattern consistent with that irregular surface; the scratches are much narrower than the size of the diamond particles.

63 responses to “The Diamond Plate Progression”

I am very surprised by the results you show – I would have expected exactly the opposite. As you said, the scratch patterns are undoubtedly a result of the size of the diamond particles and their roughness/smoothness, and also the uniformity of the surface of the diamond plate. I am surprised too by the difference between the Atoma 400 plate and the DMT 600 as I would have expected similar results from those two plates. Why would the diamonds be any different whether the plate was used for lapping waterstones or sharpening steel?

I don’t suppose you have micrographs comparing the surfaces of the 5 diamond plates you used?

LikeLike

Intuitively, lapping waterstones of various grits should leave a rougher surface on the diamonds than simply abrading steel. It would be possible to systematically study these effects, including taking micrographs of the diamond surface. However, without an industrial sponsor, it is unlikely I will investigate this in the foreseeable future.

LikeLike

Awesome write-ups Todd. Your Atoma 400 must be way less worn than mine; at your instigation (don’t know if you recall our talking about it at BF) I shaved from both my Atoma 400 and my DMT 325. Both shaved very well, to include ATG. Keep up the good work, your blog makes for great reading!

–Eric

LikeLike

Thank-you Eric. None of the plates I have used are particularly worn.

I believe you are the only other person to try the DMT 325 shave challenge.

It is telling that some people will shave from a razor honed on a rock they found in their garden, but will not try shaving from DMT 325 given the evidence shown here.

LikeLike

It would be quite a nice thing to see the difference at high magnification between a worn-in diamond plate and a fresher one also! I can’t say how many times I have had guys argue with me about wear on the plates and say things like “diamond is so hard it doesn’t wear.” Clueless!

LikeLike

Unfortunately, I cannot fit an entire 8 or 10 inch plate in my microscope. I have thought of working with a DMT card – maybe if DMT wants to sponsor some experiments…

LikeLike

Hello Todd,

Two years later I am reading about your articles.

Would you still be interested in donation of d m t s?

Please let me know.

Michal from Peru.

LikeLike

It takes a lot to wear a diamond. I was a diemaker and would use a diamond to dress grinding wheels on precision surface grinders. Years of daily use to grind a flat spot with normal vitrified Norton grinding wheels. In the days before CNC and WireEDM, diemakers would do crazy things, like dress the profile of an entire involute gear tooth into a grinding wheel, by hand, grind a punch or a hob with it, rough grind it in, dress the grinding wheel back take another pass, repeat until it’s done to the tolerance needed. The we’d take the inverse of the profile we just finished with and dress the wheel and start grinding in the die side. These diamonds dressed down large numbers of grinding wheels into dust. The do wear, but much slower than many seem to think.

Steel just isn’t hard enough, nor abrasive enough. Hardened tool steel tops out around a Mohr of 8.5, but high silicon steels like electrical steel just might have some silicon carbide in it, pretty darned abrasive stuff, wears out M2 and D2 tool steel pretty fast.

Now brass can wear spots in Sapphire, we wore out v-block guides on our wireEDM tools, but that probably took tens or hundreds of thousands of miles of wire running through the bearings to wear a little arc into it, literally around 50,000 hours worth of brass wire running though a sapphire.

Now sapphire is just really Aluminum Oxide with a Mohs hardness of 9.0, same as Tungsten Carbides (probably depends a bit on the binder and grade used though), Silicon carbide has a Mohs of 9.5 and tends to fracture and stay sharp rather than round off or flatten. Diamond had a Mohs hardness of 10.0, only exotic stuff like isotropically pure diamond is harder.

How about lapping the diamond plates against each other, coarser to less coarse (or visa versa Fine to less fine), to break them in. That should at least get some of the high spots out.

With the later SEM images it looks like the diamond plates wear sort of like grinding wheels do, the binder gives way first, and when the diamonds fracture instead of pulling out of the nickel plating they fracture like Silicon Carbide abrasives do and stay sharp.

LikeLike

In regards to the “tooth” or general use of that term, it refers to the uneven height of the apex (distance from the spine) not the with of the apex. In the above pictures it is fairly large, on order of ~5 microns which would yield a large saw/like effect in draw/slice cuts.

Note that the DMT’s when new, in the finer grades are really susceptible to clustering of the abrasive. This is so strong that in many of them they can clump so high that if they are not ground off they force edge trailing passes.

A new MXT DMT rated at 6-microns will readily produce scratches far deeper than a new fine (25 micron) just as you have seen. This is why most people recommend lapping the x-fine and above diamond plates initially, or at least taking care with lubricant / trailing passes until they even out. Otherwise they can end up just lowering the edge finish exactly as you have seen.

LikeLike

The plates I have used are definitely much smoother than when new. How the results would vary over the life of the plates will have to remain an open question. This is one of the reasons that this demonstration should not be generalized.

This particular 8k plate was essentially unusable until worked with a screwdriver shank for about 30 minutes. I have made a serious effort to smooth this plate; there are a significant number of scratches with no diamonds remaining (under an optical microscope, it appears that approximately half the surface has no diamonds remaining). I am skeptical that particular plate could ever perform as a high grit hone.

LikeLike

On page 22 of John D. Verhoeven’s pdf at

Click to access knifeshexps.pdf

the following quote relates to your interesting observation of deeper/finer scratches at putatively finer grits. Your observations and hypotheses extend/expand his casual mention,of course. Love your site.

“Interestingly, careful comparison of the edge quality of the blades done with the 2 stones indicated that the abrasive grooves were perhaps slightly finer on the supposedly coarser 6000 grit stone. The results indicate that an advertised finer grit in this 6000 to 8000 size range does not guarantee a finer abrasive action.”

LikeLike

Thank-you. I would not draw any conclusions from those micrographs. Even with high quality SEM, the difference between 6k and 8k stones of the same type would be subtle at best.

LikeLike

“Since pressure is inversely proportional to contact area, a larger smoother particle will require a greater force to scratch than a smaller or more irregular particle.”

So after reading this I would be curious to see what would happen if you use more force on the lower grits, thereby causing the larger particles to actually penetrate the steel, and much lighter force on the higher grits. Very interesting also your results and the difference between the Atoma and the DMT. I would like to see something done w/ the Wicked Edge diamond plates as well if you have time as I find my best edges off of the 1k diamond stones vs. the 400 stones. 1k seems to be much keener.

LikeLike

Josh,

I experimented with increased pressure on my 325 plate and this resulted in micro-chips at the edge. However, between the chips, the edge was unaffected (still very keen). It may be that those chips were caused by a single asperity on the plate. I also found that using lubricant (Norton oil) allowed me to hone a razor without chipping (viewed with a 10x loupe).

Again, I would not generalize these results. My primary goal in presenting these images was to show that grit size is not the only factor.

LikeLike

I’m shocked. It seems to me that the world is moving in a “reverse way”. This is the most counterintuitive thing I’ve ever heard in my life. If I had a DMT 400 I would try it for sure! However, if your hypotheses were verified, tons of theories and religious beliefs that have accumulated over the years around the concept of “smooth shave” should be destroyed in a moment (and people tend to become attached to their own beliefs). Great article.

LikeLike

When I got into honing knives and SR’s, this was one of the first resources I came across. I’m sure glad this was the case!

LikeLike

Most people believe the first explanation they are given and have a very difficult time accepting a new explanation, so it’s good that you started here.

LikeLike

Very nice article. Very clear and concise style – I appreciate that.

I have an “AccuSharp Diamond Pocket Stone (027)” purchased from the hardware store.

http://accusharp.com/products/027/index.html

One side is 350-grit and the other is 800-grit. I do not recognize the “grit” unit of measure, but assume if nothing else it provides a relative indication of abrasive particle size. At first use I deemed it almost useless for knife sharpening because it was so course on both sides.

I used it on a couple of axes for a while in place of a file, and now I can’t tell by touch which side is the 350 and which is the 800, but one side is noticeably more abrasive than the other – you can only tell by the increased friction on the steel when sharpening. I thought that was interesting, but gave it no more thought until I read your blog.

Forgive me if I lack the language to convey my thoughts.

This article makes me thing your results ought to have been obvious – we have no idea the shape of the particles but are fairly certain that diamonds won’t be worn flat by hardened steel, though any protrusions might be broken off. Any diamond particle with a shape not sufficiently supported, i.e. too sharp, will probably fracture into a less aggressive exposed surface when abraded. It really stands to reason that the smaller particles will have more support from the adhesive than the larger particles, and being smaller will offer more friction-inducing contact per square inch. Hell, the smaller particles are probably the size of what’s knocked off the larger grit elements. I imagine the fine surface as a board covered with the sharp end of tacks clustered as close as possible, while the “course” surface (after breaking in) I see as rounded beach or river gravel the size of your thumb comparatively. Course is tough enough to abrade steel but not sharp enough to gouge it, while the fine is still sharp and easily capable of carving long grooves into any surface dragged along it. I hope my lack of vocabulary doesn’t detract from what I’m saying.

That said, I’m thinking there is a simple way to see the relative diamond grit sizes and their effect. You have made me think that I might be able to press and/or drag each side into exposed and developed film to create a path for light based on the amount of material punctured or removed. Once can then project the image created to easily magnify and examine the resulting effect. I would assume film would respond to abrasion or impression similar enough to steel to make such analysis relevant. A substrate of consistent density throughout would allow a person to determine the depth of the scratches by brightness levels in photoshop after scanning. If the opaque layer was confined to the surface, one could still determine the relative size of the particles.

I’m going to give it a try, inspired by your work.

LikeLike

I don’t understand the comment: “The expectation that low grit edges are “toothier” may lead someone to believe that a toothy edge is superior in some applications.”

LikeLiked by 1 person

I plant to write an article or two on “toothy” vs “polished” in the future that will better explain these concepts.

Commonly, there is an assumption of a linear relationship between grit size and apex refinement. Very simplified, that coarse grits produce “toothy” edges and fine grits produce “polished” edges. While this does occur in some situations, it is not generally true. In the example here, we see (only visible at these very high magnifications) the inverse relationship.

My point, in that comment, is that these particular low grit edges (325 & 600) feel sharper and perform better than the high grit (1200 and 8000) blades. In this case, it is because they actually are sharper & keener, not be cause of “toothyness.”

LikeLike

This is a wonderful site. You’ve answered some of my greatest sharpening questions and turned my understanding of the subject upside down. After sharpening a higonokami on my cheap Harbor Freight diamond block’s #300 grit side this morning and shaving the back of my hand, I believe your microconvexity theory.

If more compressible surfaces -coarse sandstone and the like- exhibited the microconvexity effect this might go to explaining the ability of Western, Middle Eastern, and African carpenters of yore to plane, pare and cut very difficult woods prior to the invention of the Shapton 8k. If Moxon’s recommended sharpening method was standard Elizabethan practice -grind stone then whetstone- apparently that was enough to carve ebony into furniture. Modern mokonde sculptors carve wet Blackwood with even less.

If this works for woodworking tools -and why wouldn’t it?- I can’t justify walking my way through 5 different grits. If it takes ~30 seconds max to refresh a chisel edge on a diamond block, why bother?

Thanks again. Keep it up!

LikeLike

I would conclude that on the higher grit diamond plates, the density of the diamond is too low. By way of example

On a fine diamond stone, the density of the diamonds would have to increase at the same rate that the diamonds get smaller. If a coarse stone has diamonds of size x, then if there is a finer stone with diamonds of size x/2, then the same number of diamonds on the plate would give you 1/2 the density per area assuming an even distrbution.

I’m sure there are more diamonds on the finer stone than the coarse, but are three enough to make up for the loss in size of the diamonds. I speculate there is not.

The rough diamond stone would act like a fine tooth come if you rub your hand accroos it, there are so many teeth that the pressure is distributed such that each tooth only bears a small amount of pressure. Now take 1/2 of the teeth away, the same pressure exerted by your hand is borne on a smaller amount of teeth. Do that with something as hard as diamond and it’s going to cut in further to the steel. It could poteentially cut in as deep as the diamond is above the nickel or whatever it’s bound to. If the fine diamonds don’t make up in density what the fine diamonds give up in size compared to the coarse diamonds, it follows that they woudl scratch deeper and in a more sparse pattern.

Perhaps with current diamond plating technology, there is a limit to the density that can be achieved. Perhaps its a current technology or process limitation, or perhaps driven by price point, not sure. It would be nice for a current manufacturer to “come clean” so to speak, but I think non of them want to because it might accentuate the point that at the finer grits, above 1200 in diamond stone grit terms, you are better off with an Arkansas, Waterstone, Coticule, Ceramic, or Waterstone than with diamond, which some folks have concluded or decided on their own already. If they handn’t why woudl they be flattening watersones with diamond stones rather than just using the diamond stones.

I’ve done no tests, but this is a hypothesis based on what I’ve read here and elsewhere about fine diamond leaving scratches much deeper than expected.

LikeLike

There is a very important concept that is almost universally misunderstood and that is that the depth of scratches produced by a flat hone is much shallower than the size of the abrasive. A deep scratch is formed when one ( or a very a small number) of abrasive particles sits higher than the average surface. In this case, the pressure is enormous since the force is applied over the contact area of a single grit particle.

LikeLike

Todd, I’m too ignorant to know if you are agreeing with me, disagreeing or merely pointing out a fact I may have missed.

I will say though it seems as if we could manufacture diamonds to a particular shape and embed them sufficiently closely the higher grits would not scratch as deeply as they do.

Your results indicate, at least as far as DMT hones and this one test are concerned to stop at a lower grit and finish with a different material than diamonds.

I have a Trend 1000 grit credit card, a DMT 1200 grit credit card and an Eze Lap 1200 grit bench stone. The DMT and Trend are about equally broken in and the Eze Lap is a bit newer. The DMT leaves the worst finish of the three and the Trend the best. I’ve heard the Eze lap will break in nicely. Not there yet.

I also have an Atoma 400 that has only flattened one water stone once well over 6 months ago. It serves only as a sharpener now. It leaves a nice uniform pattern. I wonder if it would fair better under your microscope.

Lately I’ve been experimenting with the Fallkniven DC521. 600 grit diamond on one side and ceramic on the other. I like it. I can strop after the ceramic side and have a nice usable edge for my wood carving. It’s a good traveling kit. One bench stone a slip stone and a strop is all I need to be functional.

Of course wood carving tools are another thing completely as I sharpen them with the direction of sharpening parallel tot the cutting edge rather than perpendicular as chisels and plane blades are commonly done. To be clear I do strop perpendicular to the edge.

LikeLike

So far I have used the concepts presented here in restoration then use of about 10 old razors. After using the DMT 325 to repair the edge, straighten the spine if necessary and then set the bevel, in every case I went directly to a ‘finisher’, be it Nani12k, Coti, Chinese or purple Welch slate. This with Solingen, Swedish and Sheffield steel. The results in every case have been excellent and consistent with shaves as good or better than any I’ve had. Just wanted to report back and say thanks.

LikeLike

Todd, I just noticed a caption error above – you have two apex detail shots in a row captioned as the DMT325 when I think the 2nd should be the DMT600. BTW, I went ahead and shaved with a DMT325 edge again for the recent discussion at the other site – I posted some images from my scope there also. Another nice shave. It appears that the convexing on my razor is taking place in the last 6-8 microns of the bevel. I wonder if this is a variable depending on the dullness or wear on the surface of the diamond particles.

LikeLike

Thanks Eric, it took 13 months for someone to notice that typo. That DMT Fine (600) has always produced a foil edge when I have tested it.

LikeLike

Hi again. I hope it’s ok, I used some of your images to help someone new to honing regarding his DMT extra extra fine. The forum rules don’t allow me to post links to other websites, although I wish I could.

Also, when are your next findings going to be published? Any hints on what it touches on?

LikeLike

I hope that they aren’t trying to hone a straight razor with an EEF.

LikeLike

Hi Todd,

Out of great curiosity I have to inquire. Would a similar grit aluminum oxide (fine Norton India) stone give comparable results? Reason I ask is the India is around 9 on the mohs scale and just under diamond in hardness. Similarly being an oil stone it is not in it’s nature to shed any grit or once broken in at least.

What do you think?

LikeLike

I haven’t looked at the various coarse sintered stones in any detail. Certainly they can become “glazed” and produce much finer results than expected as the diamond plates do.

This type of stone is typically quite porous and loose grit can be come lodged in the pores and not flush away easily. The ‘open’ structure of the diamond plate surface will allow loose/broken grit to be flushed away more easily.

Both types of hones will shed or have grit broken (the do wear, albeit slowly),and it only takes a small number of these particles to lodge in the surface sitting higher than the surrounding (fixed) grit particles to produce a large effect.

LikeLike

Since the edge looks great after the DMT coarse, I wonder how the improvement would look like with additional denim and diamond on leather with your equipment. Particularly for knife sharpening, finishing edge leading on DMT coarse, then only denim and leather after depending on how much finish you want. Any thoughts? I’d love to see pictures with that finish.

LikeLike

Excellent work. A systematic approach to understanding the ‘arts’ often challenges deep-held beliefs. Treading on this ‘sacred ground’ can be expected to stir some controversy — the price of progress.

Philosophy aside, I have two pragmatic questions to check my understanding of some of your results.

Question #1: Am I correct here that a single honing on the 325 grit diamond plate produced a result, at least in terms of edge width, that is similar, or perhaps even keener, than achieved by honing on the 1000 grit Chosera followed by the 2k, 4k, 8k, and 16k Shaptons?

From ‘The Honing Progression’ writeup: “The convexity near the apex is removed by the 4k level, and the measured geometry is unchanged with higher grits beyond the 4k. Beyond the 4k level, the bevel polish is refined and the edge width is reduced from about 0.3 microns to about 0.1 microns.:”

From this ‘Diamond Plate Progression Writeup’: 10000x magnification of the apex cross-section after honing on the DMT Coarse (325). Edge width is less than 100nm.

Question #2: If the above result was deduced correctly, would it be reasonable to also conclude that the the equally, or perhaps more, keen edge of the blade sharpened using the 325 grit DMT stone would also be more robust sue to its more convex (i.e. less ‘sharp;) geometry near the edge?

And, lastly, what kind of generalizations and/or cautions would you dare offer with respect extrapolating results from your controlled ‘straight razor’ experiments to the more complex world of different blades (i.e. steels, geometries, etc. )

LikeLike

You are correct, the blade finished on my 325 grit diamond plate was keener (and shaved better) than one finished on a progression ending with the 16k Shapton.

Again, I don’t want to generalize this result. I have only one 325 grit diamond plate, but I was able to consistently repeat this result on several blades. I have recently been using that plate for plane blades and chisels, and at some point I will check to see if this “reconditioning” changes the results for straight razors.

My experience has been that micro-convexity improves the longevity of the blade for shaving or light tasks like cutting paper.

Although the diamond plate produces a micro-convex apex with very similar geometry to one produced by stropping, the apex will experience much greater deformation when honed on the diamond plate than it will on the hanging strop. I haven’t studied the mechanisms of dulling systematically enough yet to speculate about which would be preferred for particular applications.

The primary difference between straight razors and other blades is the small bevel angle. Below 20 degrees (inclusive) the steel is flexible and easily damaged. I haven’t systematically studied higher angles, but up to about 30 degrees the sharpening effects are similar to those observed with straight razors. With other blades, keenness (or push-cutting ability) is not necessarily the goal.

LikeLike

Hi Todd. Thanks for the excellent and counter-intuitive post. It seems like the higher grit diamond plates are removing more material for each stroke. If you had to use one of your DMT diamond plates tested here to change the bevel angle on a chisel or a plane iron by a few degrees, would you prefer the higher grit plate 8000 XXF to set the bevel, and then finish off with a coarse 325, or would you simply use the 325 all the way through?

I’m a wood worker, but not a razor shaver. You’ve changed the way I sharpen my tools. Thanks for all your work.

LikeLike

I’m cautious about generalizing since I’ve only tested the single 8k EEF plate that I own; however, the majority of other’s comments I’ve read suggest that mine is typical. I’ve also only tested the three 1200 EF plates that I own, but the consistency of these three suggests they are also typical. Keeping that in mind…

(The abrasion rate vs grit post is also relevant to this question).

I have absolutely no use for the 8k EEF – it removes metal at the same rate as the 1200 EF, but leaves substantially more damage.

(I’ve spent hours trying to break it in).

The coarser DMT plates require more pressure to cut than I can achieve when sharpening a chisel or plane blade (I use a Veritas MK II jig, which limits how hard I can “lean in” and maintains the contact angle so there is no pressure increase due to convexity. So again, I have no use for the 600 F and below.

To answer your question, the DMT 1200 EF is the only hone I use for my chisels and plane blades. It’s as fast as any hone I own (in that pressure range) and it leaves relatively little damage to the apex.

Typically, I’ll follow with a 1k Chosera or 2k Shapton waterstone (whatever is handy) with edge trailing strokes and then strop on the denim with metal polish, and finish with diamond on leather).

LikeLike

Thanks for sharing your process. I’ve been using my 8000 grit DMT for major plane iron and chisel surgery since I read the abrasion rate vs grit post. I have that in a wider format than my 1200 grit DMT, so I’ll probably stick with it for the moment just because of the ease of use, but I’m glad to know what you find useful for honing your tools.

Clearly you have a technical background, so this may be a completely useless offer but: if you’d like to run some statistical analyses on this stuff to include in your blog, I’d be happy to donate some time as a thank you for the value you’ve added to my hobby.

LikeLike

I would be most interested to know whether your 8000EEF ever becomes “broken in” to the point where it behaves like a high grit hone.

LikeLike

Great post – what DMT plate did you use? They have loads.

LikeLike

These were DiaSharp plates.

LikeLike

Thanks for the reply.

Question 2 I’m afraid;

My understanding is that the low grit diamonds create a microbevel, “shaping” (for want of a better term) rather than “cutting”, though steel is removed. Could this transfer to other large particle medium?

The reason I ask is twofold

1) I cannot afford to spend 40 quid on a DMT 325 DS at the moment

2) I have a HUGE collection of sharpening stones of various types, and have always been struck by those that have been given to me with a story attached – that their uncle used this Norton India or slab of oxidised Washita to upkeep his razor for years – and others razors.

If a razor came with said stone it often showed signs of being honed “free hand”, probably around 30-45 degrees. Could the combo of raised spine sharpening and large particle size account for it’s usefulness? I’ve added microbevels to razors (in-fact I suspect they are easier for beginners to handle) and used Nortons to set bevels, but it wasn’t ’til I read this article that I thought about Raised Spine + Large Particle Size.

Do you have any thoughts?

(I will experiment with this approach on Indias and Washitas, try my well-worn Atoma 400 for now, and one day buy a 325 dia-sharp.)

LikeLike

Ok, I bought the 2 x 6 325 mesh diasharp plate, and I’m ready to experiment. Thought I’d run a plane blade over the plate for, say, an hour or so before hand, to knock down the high spots.

LikeLike

Although I’ve never used it for a razor the 325 mesh plate is my favorite “stone” for sharpening. For anything but a kitchen knife I use this and 3 micron spray for 5 or less stropping passes on balsa. Now I know why I’ve always gotten such a good edge from this. For kitchen knives Indo use a 1200 atoma after the DMT and then 15 or so passes on the balsa. I’ve found the atoma leaves an edge very similar to a ~1k waterstone

LikeLike

Out of sheer laziness, leather striping is impractical. If a chef can use one stone to get 95% sharp kitchen knives it seems the 325 grit DMT magic. Please elaborate on your technique.

Were your strokes trailing, leading, or were you setting the bevil?

Starting condition of the blade?

Expectation if one were to trail with the 325 and convex with a ceramic rod?

LikeLike

so fascinating, thanks!

LikeLike

Hey Todd!

This is fascinating! Your blog brings some sanity to the otherwise folk-lore laden space. I’m constantly in search of more practical means of sharpening so this post was quite the discovery for me.

I’ve replicated this result this morning using a 325 grit Sharpal diamond plate and a vintage kamisori. I performed ~7 sets of 7/1 omote/ura leading edge strokes. The razor happily treetops arm hairs and provides a both close and comfortable shave. Needless to say this is a pleasantly surprising result but I am wondering;

a) In the 6 years since this discovery are there any additional insights you’ve garnered? For example does (bare) stropping help or hurt the edge? Does polishing on a very fine stone help, hurt or have no discernible effect?

b) What implications might this have for chisels and planes, specifically single bevel laminated Japanese blades? The process is seemingly to sharpen the bevel and then perform burr removal on the back of the blade using your finest stone. Coupling the knowledge in the Burr Removal articles with your findings here I’m envisioning a process in which sharpening is done bevel only with the DMT 325 and then both sides are stropped to remove the burr.

I’m curious to hear your thoughts, and thank you for all the great articles!

LikeLike

I may have just answered my own question a through some experimentation here. It seems it treetops hairs best directly off the 325 plate. Presumably stropping can be used to maintain it so you don’t need to take it to the diamond plate every time. This is a very pleasantly practical outcome. It makes razor maintenance trivial.

LikeLike

Really, the only obstacle to maintaining a razor on the 325 plate is to suspend your belief in all the things you’ve read on internet forums about “grit” and “grit progressions.” Basically, there are two fundamentally different ways to make a keen razor edge; one way is by burnishing with larger particles that don’t have sharp corners, like a broken in 325 plate, barber hones or natural stones and the other way is by using extremely high grit stones like the Gokumyo 20k.

LikeLike

I fully buy it. I toyed around with it a little yesterday to convince myself and the best edge was the one simply straight off the 325 plate. A few strokes produces no swarf visible to the naked eye which eliminates the concern about on stone maintenance causing unnecessary wear.

Thank you, truly, for sharing the insight here. You’ve greatly simplified my razor maintenance procedure.

LikeLike

A couple of things come to mind – honing oil is very helpful with the diamond plate in this application. Bare stropping with leather is critically important if only for the fact that it applies a lubricating layer to the edge, similar to that on coated razor blades. Bare stropping on linen is more complicated – for a micro-convex edge is doesn’t do much, for a triangular edge it can be damaging and for a chipped area it will restore the edge somewhat, at least easing the corners of the chip.

The reason you are able to produce a keen edge on the 325 plate is that you are working at a pressure where burnishing occurs – and too low for grinding/cutting. With a chisel bevel, particularly freehand, you are generally going to exceed that pressure threshold and form a burr that won’t be removed easily with a fine stone from the back.

LikeLike

> With a chisel bevel, particularly freehand, you are generally going to exceed that pressure threshold and form a burr that won’t be removed easily with a fine stone from the back.

Presumably this is the reason for the edge trailing strokes on a 1k or 2k stone you detailed for plane blades in another comment? I apologize if my questions are naive or ignorant — I have a much poorer understanding of the mechanics than you and have been subject to a lot of misinformation over the years. I’m hoping to take this insight and greatly simplify my chisel and plane honing procedure as well. If I’m reading your procedure for planes correctly;

1) Sharpen on DMT 1200 with Veritas Honing Jig (As opposed to DMT 325 because you cannot generate necessary pressure on the 325 with the jig.)

2) Trailing strokes on 1k or 2k, whatever is handy to remove burr generated in step 1.

3) Strop on denim with polishing paste to introduce micro convexity presumably?

4) Finish on 0.25 micron diamond paste leather strop.

LikeLike

i recently got hold of about 10 antique razors. in workable condition.

so i decieded to hone them up on some various stones and test shave. bear in mind i’m not usually shaving with straights.

morihei 12k, a suita, a coticule, imanishi 10k. then leather.

test shaved and all were tugging. not sharp enough. and i could tell i was at the very edge with all of them when sharpening them.

even used a marker.

tested them. none would pass the hht. or chop arm hair.

so obviously this was the reason i couldn’t get a shave out of them.

i re-did them all on various stones and stropped much more and now they’re starting to pass the hht and also chop some arm hair. except one… a swedish erik anton berg, appears to be full hollow. no matter on what stone i honed it, it would not pass the hht or even begin to chop arm hairs.

then i decided to break out the dmt 325 just for fun. gave it some pressure then light pressure. then leather. some circles then edge leading, alternate sides.

and today i tried shaving with the razor. and it shaves!!! lol. no tugging. not at all surprised but still kinda funny. the shave itself was quite misreable since it was basically my first full complete straight shave. so it is what it is.

yeah dmt 325 works for shaving. i can vouch for that.

LikeLike

Hello,

Have you tried DMT Medium Extra Fine hone? They claim it to have 6 µm particles.

I own three of these fine dmts [EF, MEF, EEF] and this one somehow seems to be the least aggresive [maybe just mine?]. Would it be possible that they don’t spoil MEF with oversized diamond debris? [well, it doesn’t even have its own dmt color..]

Thanks for these pictures, I was quite surprised trying to sharpen some chip carving knives with EEF first time..

LikeLike

I’ve considered buying one to confirm what I already suspect. I don’t believe the oversized diamonds are accidental. Deliberate addition of oversized particles is more common than people know.

LikeLike

Why would they do that – put in oversize particles?

LikeLike

My speculation is that they will act as a anti-wear layer to extend the life of the plate, and they will provide burnishing action which is probably critical to the overall performance. Once they smooth out, they shouldn’t contribute too much to grinding, but the problem is that they take too long to smooth out, if they do at all.

LikeLike

Thanks for your detailed analysis and explanation!

In your straight razor honing method, you suggest using 1000k and 6ish-k stones, prior to a pasted denim strop. How would just the DMT325 to pasted denim compare? Would that be an effective single “stone” technique?

LikeLike

(My) DMT Coarse is very peculiar in that it produces a very fine edge when used as a “finisher” for a straight razor. Normally sharpening on this plate produces wicked burrs, which many people seem to love. It can’t work as a single stone for razors because of those giant burrs that form with extended use, but it seems that it could substitute for stropping in my “simple honing” process, when used with a SG4k or similar to set the bevel. I had outstanding results with a few light passes with honing oil as lubricant.

LikeLike

Hi Todd,

I am new to sharpening – I have used sandpaper glued to a glass plate to sharpen chisels and plane blades (carbon steel). I recently tried using some cheap Chinese poly-crystalline diamond plates (HTS) to sharpen card scrapers and a hss blade both for a scraper plane. Can you please explain the role of a finisher? I am getting a leather strop and jende diamond emulsion (1 micron) – is it ok to go from 300 grit (45 micron) Atoma to the strop? I also have the usual green and white buffing compound. I rèad after writing the above that you use a 2k shapton and a denim strop before the leather with diamond. What is the benefit of the 2k stone given that the grit size is almost same as the 1200 grit diamond? I suppose it has to do with the way grit particles wear off on the stone? What is the grit size of the metal polish (this is either aluminum oxide or chromium oxide?)? And the size of the diamond paste grit?

My mind is probably too brainwashed with the grit progression folklore, but is it not faster to hone on a 300 grit Atoma and then the 1200 than using the 1200 all the way?

I’m experimenting with putting a hook on a TC plane blade by honing it at successively higher angles going closer to the tip to approximate a hook (coz I don’t want to apply too much force and remove the diamond off the plate like I did with a hss blade on the HTS plate). Will plastic deformation at the tip itself do this without having to apply much force? Would just increasing the angle by (say 7 degrees) in one shot also burnish a hook as opposed to slowly increasing the angle? Is the hook likely to be stronger if one increases the angle in small increments? I’d appreciate if you can share any intuition you have – even if you are not certain. I understand that I probably just need to try it out and see what happens – just more comfortable doing it with some advice.

Thanks,

Arvind

LikeLike

Chisels are particularly difficult because of the burrs that form from working just the bevel side. Coarse diamond plates, in particular, tend to form large burrs. Something like a 2k Shapton Glass or similar is better option because of the slurry that will form – it will both speed up the grinding of the back and minimize the size of the burr.

Coarse grit hones are NOT faster unless you provide sufficient pressure to surpass the grinding threshold. For the back of a chisel or plane blade, it is very difficult to apply sufficient force to achieve that pressure because of the large surface area. For those, we want to use a stone that produces a bit of slurry to apply 3-body abrasion.

“TC” is Tungsten Carbide? Normally W is short for Tungsten (Wolfram). Tungsten carbide isn’t going to deform as steel does and I don’t how a hook can be formed without plastic deformation.

LikeLike

You says that Dmt 325 grit can provide shave ready . Have you shaved comfortably with it? I ask it because for me this is impossible! being a low grit! and a diamond stone that leaves big scratches! Second think I can’t understand: You says going up the blade is worst and this is obvious even if you will not have done experiments! But I can’t understand your conclusions! What is your conclusions about the diamond stones for honing? I know big professional using 1000 k and 3000 k diamond stones for setting the bevel but not for making the razor shave ready! Anyway do you think a diamond stone can be used to grind or hone a straight razor? have you tried it with a razor that has a cutting edge too tick to be honed on a whetstone? All we should know whetstone are not able to grind a blade!!!! So probably a diamond stone 1000 k should be used for that reason but all the world do the contrary using a wetstone !!! What about dulling completely a blade and lose the completely tha apex and bevel? and try to hone without a diamond stone? I think you should try it! I have tried and my experiment tell me is impossible to hone without a diamond stone!!! water stones can cut enough to form an apex!

If we remove completely the apex the waterstone will not able to create again it!!!!!! you should try this experiment and use a Naniwa diamond stone! that is much better than DmT because the diamond are inside resin and not put on simple metal!!!! More effecient and more fast and smooth! and more expensive !!!!!!!! If we lose the bevel completely the razor will be dead ! Only a 1000 k diamond can solve the problem perhaps ! Because there are differente kind of dulling! and different kind of steel!!!!!! and shape of razor!!! Think about it and you will open a new door on straight razors!!!!

LikeLike

I don’t make any claims that aren’t backed up by experimentation. Yes, I have honed multiple razors with my DMT Coarse and shaved comfortably, as have multiple other people who have tried it.

LikeLike

lol lol lol. all the excitement to the end of this comment makes me laugh out loud. if only he had read your blog and understood everything he believes you have done and proven inverse for the most part. lol lol lololol. im here for the comments sorry lol ive read your articles about 15 times each and love the comments.

LikeLike