Stropping a blade on a clean (without abrasive) substrate achieves FOUR results:

1) REALIGNING THE EDGE

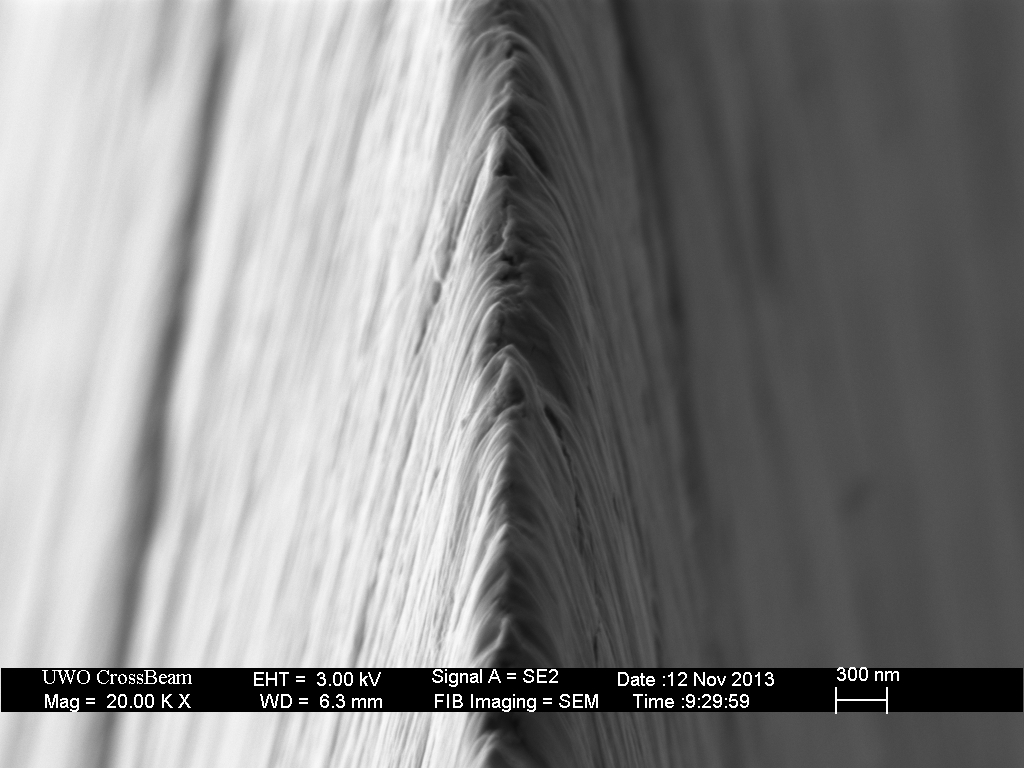

Although a straight razor is made of hardened steel, the edge is flexible and malleable. Below is an example of a relatively large ‘ding’ in the edge. I received this blade from a custom razor maker with this defect and can only speculate as to the cause. The blade was stropped 50 laps on clean linen, 100 on clean horse leather and then 10 on clean linen (to remove residue from the leather). The same location on the blade was imaged, clearly showing the blades’ edge has been realigned.

Realignment more commonly occurs at much finer scale; the above series of images was chosen only for the clarity of showing the same location on the edge before and after stropping.

2) BURNISHING

Burnishing refers to the movement of metal, distinct from abrasion and the removal of metal.

The burnishing effect is most clearly observed at an area of the edge that was previously chipped. This leaves a near square corner, and the easing of this corner occurs with metal pulled up towards the edge. Burnishing also occurs on the bevel face, smoothing asperities by plastic flow (this can be observed in the series of images shown below, where both abrasion and burnishing occur).

3) ABRASION

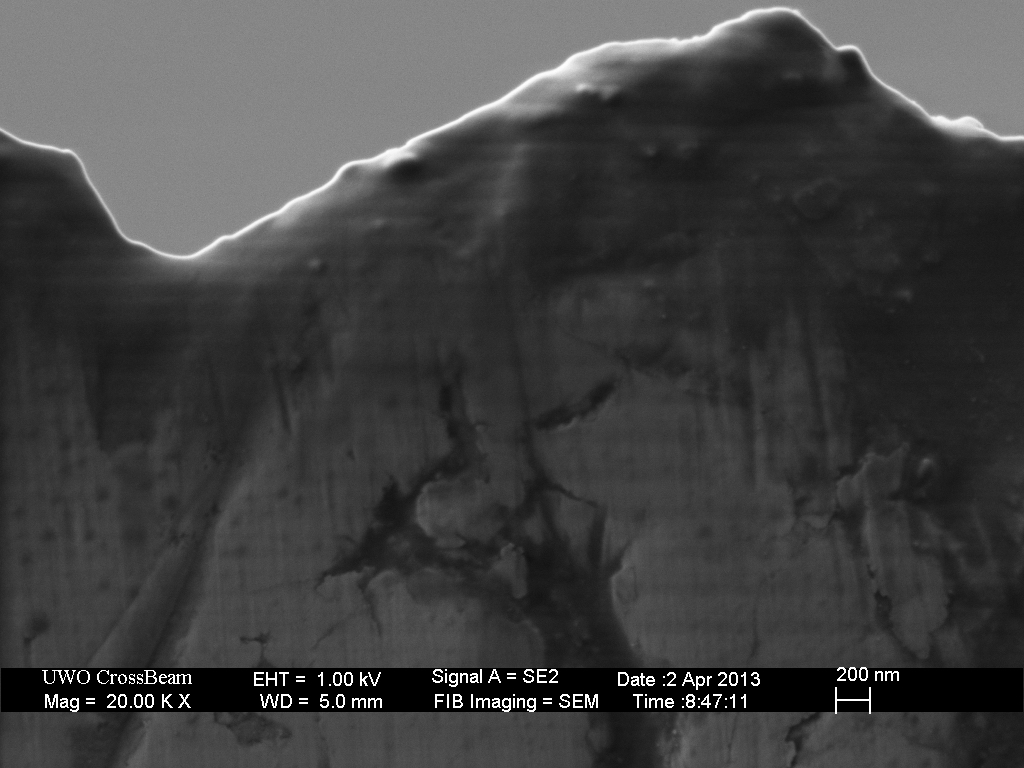

Abrasion (the removal of metal) occurs by two processes; nano-scale abrasion and edge chipping. The series of images presented below were taken from the same location on a razor (as witnessed by the x-shaped pattern in the top right of the images). The softening and loss of scratch definition occurs primarily by surface abrasion in the last 2 or 3 microns of the edge, increasing both keenness and sharpness.

Abrasion by micro-chipping is manifested primarily through the removal of weak or damaged metal at the edge and occurs more rapidly with stropping on linen than leather.

4) COATING

Manufactured razor blades are typically coated with a lubricating coating to reduce the force-to-cut and improve the apparent “sharpness.”

For SEM imaging, this coating blocks the view of the metal edge and I normally remove it prior to imaging stropped edges (as, for example, in the images above). It is, in fact, extremely difficult to remove. (In an optical microscope, these coating is transparent, although they may impart color due to interference effects). The effectiveness of this coating in lubricating the passage of the blade and thereby reducing the force-to-cut is yet to be determined.

68 responses to “What does stropping do?”

I just found this blog and it’s great! You also managed to create a great setup for making photographs. (Are they SEM images?)

Your blog examines some issues I’ve also tried to examine on my own blog. I love the clear way in which the pictures demonstrate the various effects of stropping. However… I still don’t see how the pictures illustrate burnishing. The last picture in the burnishing section seems to show a much rougher edge than the pictures before.

LikeLiked by 1 person

Thank-you Mark, I have been following and appreciating your blog for some time. Yes, these are SEM images. They are different than other images you have seen in that I use low electron energy and I clean the steel prior to imaging. In fact, we briefly discussed some of them on the Wicked Edge forum last year.

In this post I have presented just one or two images that demonstrate each of the effects. I agree that burnishing is the most difficult to see, and really deserves a separate post and additional images.

In the image series I present here, stropping on linen causes the edge (which is initially about 150nm wide) to be broken (or micro-chipped) away leaving and “squared-off” edge 300-400nm wide. This part of the process is abrasion, in the sense that micro-chipping is the removal of metal. However, continued stropping on the clean linen results in plastic flow (burnishing) of steel from those squared corners UP and over the existing edge, first forming a crown-like shape and then a new apex. Further stropping on clean leather will abrade the edge, thinning it and improving keenness.

To be clear, this is not a successfully honed straight razor; however, the process of reforming micro-chips through stropping is the mechanism by which a blade is maintained in shave-ready shape with stropping between uses.

Burnishing also occurs on the bevel face where scratches are smoothed out; this is easier to see at higher magnifications. Close examination of the “abrasion” series does demonstrate the burnishing effect.

Todd.

LikeLiked by 1 person

Todd, This is a great blog! Thanks to Mark for posting it on the Wicked Edge forum 😀 Thanks for all the research and work you are doing!

This article is interesting… Your work on plain leather/burnishing/re-aligning the edge seem to contradict Dr. Verhoeven’s findings in his paper, “Experiments on Knife Sharpening” in which he concludes:

“The experiment with stropping clean leather confirms the previous experiments. The natural abrasives present on clean leather are not adequate to remove edge burs or surface abrasion grooves on stropping.” (bottom of page 36, http://www-archive.mse.iastate.edu/fileadmin/www.mse.iastate.edu/static/files/verhoeven/KnifeShExps.pdf).

I would love to see more research on this topic. Thanks!

LikeLike

Josh,

My interpretation of the comments in John’s manuscript is that the stropping effect is not visible at the resolution and contrast provided by his SEM images.

The effect of stropping with clean leather is subtle and occurs primarily over the last few microns from the apex and requires much better quality images to observe.

Todd.

LikeLike

Todd. When you refer to clean linen and clean leather, what exactly do you mean by this? I treat my strop with a paste and the linen side I use an abrasive powder. Is this the wrong way to set up for stropping a straight razor? I would greatly appreciate a reply as it would be helpful to me in maximizing the sharpness of my razors for shaving.

Thanks

LikeLike

Ideally you have a “good” linen/leather strop for you daily stropping that has no abrasive, and an “OK” leather strop for the .25 micron diamond. I wouldn’t put abrasive on the linen component of a $200+ strop.

LikeLike

I am interested in the possibility of using SEM to evaluate the sharpness of hypodermic needles used to place catheters into veins. ¿Are you aware of anyone who has studied this?

LikeLike

I’ve not come across any published work on this. It is something we can do though. Contact me at scienceofsharp@scienceofsharp.com if you want to discuss the cost.

LikeLike

I apologize but I do not follow. Stropping on linen degrades an edge? Should I not use my linen strop. I have a pure flax linen and was unaware it was making my edges duller.

LikeLike

After more than a year and thousands of visits to this page, you are first to comment on this surprising result…

The answer will depend on your point of view. We could call this removed metal a “burr” or a “false edge” and be happy to have removed it. It is important to understand that the “broken-off” edge will continue to be refined by the linen strop, so this is one (of many) approaches to honing and stropping a razor. A razor which has been successfully finished with a pasted strop (micro-convex) will not be damaged by the linen, although it may not be improved either. A razor micro-convexed by honing with slurry may be unaffected or improved by the linen. A razor honed on very high grit synthetic hones (triangular apex) is usually degraded (initially) by linen, as shown here. You can easily test your own situation with the hanging hair test or by tree-topping arm hair.

In my experience, metal that is removed by the linen strop would not survive the first shave. Undoubtedly, there are people who happily shave with burr-edges.

In the longer term, linen will refine micro-chipped areas of the blade, and this is certainly a positive effect.

LikeLike

I’ll have to try going right to leather and skipping the linen. I finish on a Black Arkansas and the edges I get are agreeable, smooth and sharp. Maybe they will improve without linen?

I just found it odd after all the praise of using linen and all the other plethora of synthetic materials before going to your leather strop.

LikeLike

hello todd, First of all, thank you for your work, I find the contributions and comments very helpful. but i have one more question to which i have not yet found a correct answer. Will a razor be microconvex if I sharpen it on a 10k synthetic stone with 10k slurry? and what would be better in that case, edges leading or edges trailing? I hope you can help me, greetings Eric

LikeLike

It’s quite a bit more complicated.

Typically a slurry on a high grit stone will remove any burr, but doesn’t directly lead to micro-convexity, but it should minimize the probability of producing a foil when you follow with stropping (basically because you have removed the steel that would become the foil).

Micro-convexity directly off the stone typically results from burnishing action on larger particles in the substrate, although the 3-body action of the slurry may soften the surface of the steel to make burnishing more effective.

LikeLike

hi todd, thanks for the quick reply If large particles in the substrate are responsible for the microconvexity, natural stone should produce a microconvexity. have you observed this with other natural stones (thuringian or jnats), or does it only do the coticule? I hope you can help me again best regards Eric

LikeLike

JNats and Arkansas, yes. Thuringian seems to work by a slightly different process.

LikeLike

I recommend that people experiment for themselves using the information here as a starting point and also to help understand their observations.

That said, I personally only use the linen component for cleaning the blade after shaving with 4 or 5 very short, light strokes. I typically use linen or denim with abrasive as part of my honing routine, however.

LikeLike

Have you taken a look at the comparative effects of different “second component” materials? Opinions on some of them vary widely within the community of straight razor shavers, eg. some folks think nylon webbing is the bee’s knees while others think it accomplishes nothing at best. Strop tension and pressure are sort of elephants in the room in these discussions, usually, but it stands to reason that different materials would act differently ceteris paribus.

LikeLike

I have looked extensively at the results from flax linen (Scrupleworks strops) and denim strops (Levis 501). The primary effects are basically indistinguishable between those two. I only looked briefly at the results from nylon weave (Walking Horse strop) and can’t make any definitive comment on that. There will be differences in speed. The challenge, for someone without an SEM, is how to compare results from different fabric components. Fabric is not (in my experience) suitable as a final strop, so observing properties related to keenness (like shave quality) is not particularly informative or even misleading.

Strop tension and pressure primarily determine the rate that the effect is achieved. For example, heavy pressure for 10 laps on flax linen gives the same result as 100 laps with light pressure.

LikeLike

O.k. O.k. Strop tension. Heavy pressure and light pressure are rather vague and somewhat obfuscating. Are these just very general terms left to ones imagination as to what heavy and light are? Would you please clarify this so it makes more sense.

LikeLike

Light means about 1/2 pound force equivalent, heavy a few times that.

LikeLike

I do agree with all of the ideas you’ve introduced in your post. They are very convincing and can definitely work. Nonetheless, the posts are too short for novices. May you please prolong them a little from next time? Thanks for the post.|

LikeLike

My goal with this blog has been to show and explain what actually happens during common sharpening/honing/stropping processes. I’ve never intended this to be a guide for beginners, but rather to help people understand what is happening when as they develop their own techniques and methods.

LikeLike

Will stropping on linen post naniwa 12k rip off the edge like the suehiro 20k? Should I go straight to leather like you suggested for the suehiro? Thank you.

LikeLike

I don’t have that particular hone, but I would expect it performs similarly to the Shapton 16k. Triangular, but typically not quite keen enough without stropping to slightly micro-convex the apex. Leather alone should be sufficient. Obviously you can just try for yourself.

Stropping on linen will remove “weak” steel as part of the process of micro-convexing the apex. So “ripping off” the edge isn’t necessarily bad, provided you strop sufficiently to re-profile (micro-convex) that broken apex. This same process occurs with use (shaving) in any case, so you can’t “preserve” that weak steel by avoiding the linen.

My personal recommendation is to use a pasted denim (linen) strop as part of the honing procedure to avoid this concern altogether.

LikeLike

When I look at your micrographs, I don’t see a sharper edge after stropping. This seems consistent with Verhoeven’s work, and with what Howard Schechter says about finishing with a Shapton 30K stone and touching up on a hone weekly. Have I misinterpreted? (BTW, just out of interest — have you tried a Shapton 30K?)

LikeLiked by 1 person

Using my definition of “sharp” you are correct, stopping does not sharpen. What stropping does is improve keenness through micro-convexity.

Unfortunately, Verhoeven’s SEM images (from the unpublished manuscript) are not of sufficient quality to reveal what actually happens to the apex during stropping.

In my experience, a typical straight razor with a 16 degree bevel angle cannot maintain a triangular geometry for any length of time. With edge-leading strokes only very high grit stones like the Gokumyo 20k or Shapton 30k can produce a triangular bevel with sufficient keenness for shaving. Coarser stones (eg Shapton 16k or Naniwa 12k) can also achieve this with care (usually a couple of edge trailing strokes will do it).

With use, or when stropped on linen, those triangular bevels will micro-chip and lose the initial keenness. With sufficient stropping (particularly on linen), keenness is restored through micro-convexity. With repeated use and stropping, all blades become micro-convex.

The approach that Howard suggests is to maintain the triangular bevel by “sharpening” with the Shapton 30k after each use and only stropping on leather to apply lubricant (strop oil) to the blade. As I have mentioned before, you must avoid the fabric strop if you want to maintain the triangular bevel.

LikeLike

Great blog posting. I had only thought that stropping would remove burrs but you show convincing evidence that it can both reform metal and add lubricant. Most impressive work with the SEM. Opticians recommend using microfiber cleaning clothes instead of tissue paper because the cellulose products have microabrasive inclusions (maybe some sort of calcium silicate?). I’m guessing your linen strops are taking advantage of that fact.

LikeLiked by 1 person

I don’t know where the “natural silica” myth comes from. I’ve analyzed a variety of strop leathers and not found even trace amounts of silicon in any of them.

The reason for using soft cloth is that foreign particles (dust) falls into the weave and so there is not sufficient pressure to cause a scratch. This is why denim/linen strops are so effective and why we can achieve a mirror finish with metal polish containing 100 micron aluminum oxide particles.

LikeLike

When it comes to stropping on clean leather, do you notice any difference between leather types? Does a Kangaroo leather strop abrade and burnish more than a buffalo leather strop? Or a Latigo leather strop? Or is the difference between them minimal?

LikeLike

In my experience, the preparation of the leather plays a far larger role than the differences between individual animal hides.

LikeLike

Um, right. Remind me again, what are the different types of preparation? I forgot… or maybe I never knew

LikeLike

I’m referring to both the tanning process used and the technique used to flatten the leather.

LikeLike

Would you be willing to elaborate? So much of what you’ve shared here has been counterintuitive. In your experience, what tanning and/or flattening methods produce the best results?

Thus far my only two points of reference have been American Bridle and horsehide. It may be pure imagination on my part, but the harder surface of the horsehide seems to leave a cleaner, keener edge.

LikeLike

Indeed, I was after a bit of elaboration as well. The terminology I usually encounter is “draw”: some strops are sold as having “just a huge amount of draw” (Buffallo leather), some as having “medium draw” (Kangaroo leather), etc. Those of us who are spending time looking at SEM images of razor edges undergoing various honing techniques are most likely here to optimize every aspect of our sharpening techniques… this particular aspect still requires some development.

LikeLiked by 2 people

I’ve seen no correlation between draw and effectiveness. I believe that the primary effect of razor stropping is to apply a lubricating layer to the near-apex, and any type of leather, including the palm of your hand, can accomplish this.

LikeLiked by 1 person

Very nice discussion of a difficult phenomenon

LikeLike

I’m still unclear about the value of burnishing that occurs during stopping on clean leather.

Application of a thin layer of lubricant to the freshly finished edge aside, what benefit is derived from pushing metal onto an already keen edge? Once you have created that keen micro-convexed edge with the pasted denim and then further “keened” it with the diamond pasted leather, it seems as though burnishing would reduce the keenness (i.e., by widening the edge).

Or is it that burnishing is only desirable for repairing micro-chips in the edge that occur due to use?

LikeLike

The term “burnishing” has two meanings – it can mean moving or pushing metal without abrasion, or it can mean abrasive polishing at the “atomic” level (ie without swarf). Typically, (clean) linen strops perform the former and (clean) leather strops perform the latter.

The only time I have clearly observed the moving of metal at the apex is with the clean linen strop at a microchip. With use, a razor will form microchips, and the linen stropping smooths these out. I would not expect that linen stropping an undamaged, appropriately micro-convexed edge to have much impact.

The leather strop can slowly abrade metal from the side of the apex and make it keener. In my opinion, the addition of sub-micron diamond abrasive only speeds up this process. So again, I would not expect any effect of the clean leather strop (at the same pressure and with leather of the same resiliency) on a razor honed with diamond-loaded leather.

LikeLike

Thanks for the clarification. I misunderstood your admonition to use only 2-3 light passes on clean linen as necessary to avoid micro-chipping the edge (as exhibited in picture six above).

If the apex has been appropriately micro-convexed, will occasional re-stropping on diamond loaded leather help to keep the edge as keen as possible between full refreshes?

LikeLike

So I was wondering about the actual technique of stropping? What direction should you strop a blade? I always thought to reallign the edge that you need to strop at 90 degrees to the edge a clean pull or push against the strop maybe a little angle to it?

Doesn’t stropping take and straighten out the microscopic fingers of steel that make up the edge and that will curl and bend when you sharpen and you want them to straighten out and align like saw teeth on an edge?

LikeLike

Stropping is always done in an edge trailing (spine leading) direction. There can be some lateral motion – this is helpful if the strop is not flat or if the blade is longer than the strop is wide. The angle should be no higher than the sharpening angle (bevel flat on the surface). For a hanging strop the angle can be less and contact made via the flex of the strop.

This article shows what stropping without abrasive does.

Stropping with abrasive is described in the pasted strop series.

LikeLike

Hi,

I just ran across this blog. Interesting info! I just ran across a problem with my straight. I refreshed my edge after 60 shaves on balsa with chrox powder. It brought my edge to new again, but only after 7 shaves I noticed some light glints on the apex. So can a hard substrates like balsa cause a wire edge to form? I thought maybe I may have formed a wire edge on the balsa and chrox. Maybe the reason the edge was damaged was because I formed a wire edge on the balsa and it eventuallay fell off and caused the damage??

I also got some questions about linen for daily maintenance. So I read you said that linen may cause micro-chipping or something like that in those lines. So you would not recommend a hanging linen as a daily maintenance tool? Only leather?

LikeLike

Stropping on balsa can produce a wire edge (just like edge trailing strokes on a stone) if the surface is over-loaded with compound, binding up the loose wood fibres on the surface.

Linen will cause microchipping if the apex isn’t already micro-convex.

These are some of the complications that are avoided by using my simple honing procedure.

LikeLike

So linen should not be used because will damage the edge? I Thought bare flax linen helps improve/maintain a shaving edge along with bare leather? Im a little confused now??

LikeLike

Once the apex is micro-convex, the linen will not cause damage. If you start with a triangular apex from a 20k or 30k stone, the linen will damage it.

LikeLike

It’s complicated. In general; if the apex is micro-convex, linen is great; if the apex is triangular, linen is bad ;however, there are exceptions to this. The only advice I can give you is to try with and without linen and see which you prefer.

LikeLike

Sorry for all the questions, but this is valuable information that you put out! I’m like a kid in a candy store! Lol So, when you say microconvexing vs a perfect “V”. Do you mean convexing on a (nano scale) to were the only way to perceive a difference between a micro convexed edge and a perfect V edge is with the SEM high magnifications, because its on a nano scale?? So a perfect V is achieved by high grit synthetics and a micro or nano convexing is produced with a slurried natural stone? The same perfect V can be created on a natural with zero slurry?

If So, I now know my problem on why the balsa and crox created the wire edge on my refreshed razor. Because their is no give in the material and therefore impossible to remove a wire edge, but it created one. The sharpness lead to 4-5 more shaves, but when the wire edge feel off during my 5th shave the edge crumbled and failed? So what are your thoughts on using rock hard felt 0.80 density or just hard felt 0.70 density glued to wood to micro convexed the edge after honing and before stropping on linen and leather. From what I gather the 0.80 has no give and the 0.70 has a little give. I’ve read that rock hard or hard felt can be used with or without compound to remove a wire burrs. So do you think its abrasive enough to micro convexed and remove burrs without crox, or do you think it needs a small amount of compound sprayed on it? If you do recommend, Which density do you recommend?

LikeLike

What’s Happening i am new to this, I stumbled upon this I’ve found It positively helpful and it has aided me out loads. I hope to contribute & aid other users like its aided me. Great job.

LikeLike

It had to be done… a visual progression of the 6 strops in one GIF.

https://ibb.co/qdDgKhb

LikeLiked by 1 person

Well, right or wrong thanks for the information. My strop has a linine side of which I powder up with a mildly abrasive diatomacious earth albeit I still cannot pass this test yet my razors still seem to do the job rather well. I do have to resharpen more than might be typical.

LikeLike

Thank you so much for the information on these pages, I’ve learned a very bunch based on the contents.

One thing makes me curious on regards of the leather strops.

Is actually dying influences the stropping attributes of the leather?

Does dye possibly adding some abrasive property to it and if yes – how does this affect the blade?

In most of the cases the leather strops are made of the undyed leather, but there also couple of suppliers out there offering leather strops which are dyed.

Thanks in advance

Have a good day

Philipp

LikeLike

A number of years ago, I did analyze a variety of strop leathers, and couldn’t find even trace amounts of metals from the dying process. For example, It does make sense that chromium tanned leather might have chromium oxide particles, but I didn’t find any.

I have found that abrasive particles much smaller than 1/4 micron really don’t contribute anything to keenness (obviously they polish the bevel face). I strongly believe that “abrasives in leather” is a myth, but it’s a difficult thing to prove. Certainly I’ve seen no evidence to support the idea.

LikeLike

Great articles.

I think Buffalo leather is supposed to be the best leather for strops, the reason being it has more natural silicates then other leathers. After Buffalo it would be equine (horse) leather. I’m not sure if it’s American Bison or water buffalo, I’d have to find out which was the superior.

LikeLike

I don’t know where the whole story about “silicates” in leather started, but there is no evidence of natural abrasives in leather. As far as I can determine from my research, silicon is present in leather as molecular Si(OH)4 or “monomeric silica” and that isn’t going to provide any abrasive action.

LikeLike

Yeah, that’s what I got from reading your article. The whole buffalo or horse leather thing came from an old-timer on one of the knife forums. He chose vegetable tanned leather over chemically tanned leather. The post was about a decade old.

This is his method for making a mounted strop:

I wet the leather well, let it sit for an hour or two until the surface color starts to come back, then roll it for 5-10 minutes with a cooking rolling pin. (A heavy marble rolling pin works best for this.)

This helps to bring the natural silicates to the surface of the piece.

After the leather dries completely, I mount it on a piece of wood using contact cement spread very thinly to keep the leather smooth and flat.

When I strop convex edges, I put a very thin piece of softer leather between the strop and the wood, leaving the strop with its rough side up.

__________________________________________________________

I imagine it produces a nice strop, but like you said, there’s no evidence of those silicates having any effect on the blade when stropping.

I’d imagine that the way the surface of the leather was prepared, and how dense the leather is, is what determines how well a strop works, along with good stropping technique.

Do you have any thoughts on what makes for a good strop?

Thank you.

LikeLike

Can regular stropping alone (with or without polish) reshape/burnish the mushroomed edge of a dull blade and restore the microlevel? Or are you better off steeling or applying a fine hone?

LikeLike

It depends. In harder steel the “mushroom” is usually brittle and can be stropped away with a rougher surface like denim, smooth leather not so well. Abrasive stropping will certainly work. Microbevelling with a honing steel is a good option. Microbevelling with a fine hone will work too, of course.

LikeLike

Dear ScienceOfSharp, with your permission I would like to include some of your SEM images on this page in an upcoming enginering book project. Would you be able to send me an e-mail so we can discuss it further? Best regards.

LikeLike

you can email me at scienceofsharp@scienceofsharp.com

LikeLike

Can you point to a link, or elaborate, on your stropping technique so I can reproduce it? How do you hang the strop? How do you maintain the blade angle ? How do you measure forces, etc? Thanks.

LikeLike

Stropping is very forgiving of technique, so provided you can evaluate your progress by some testing procedure (like tree-topping arm hair, for example) it’s just a matter of practice.

I typically keep the knife fairly flat to the the strop (lower than the sharpening angle) and bring the angle up by adjusting the slack on the strop and the downward force on the blade. With practice, you can identify the correct forces from feel and sound.

LikeLike

An elderly traditional joiner of my acquaintance (he could ‘freehand” perfect dovetails and made up his moulding planes from old large circular saw blades), honed his chisels/plane-blades etc.on a piece of sheet aluminium(uk!). I have never heard of this practice otherwise. Works for me with 2mm sheet. Anyone else use this method. ?

LikeLike

You can make a lap with aluminum by embedding abrasive, just like you do with cast iron.

LikeLike

Hi,

I have a few questions. So if i strop 15 laps on a strop loaded with 0.5 micron diamond to remove trace of burr with a foam backing and slightly convexed my apex on my razor. My next step i want to use .25 micron on a firm loaded balsa strop. So wouldn’t i need to tape the spine after the stropping on the strop with compression, when i move on to the flat hard strop? The reason i ask is because i already increased the angle on the foam backed strop so if i didnt tape to raised the angle then the apex would not be in contact on the firm strop. Would it?

LikeLike

Micro-convexity comes from the surface texture, like the dangling wood fibres on surface of the balsa strop. This is why they don’t work if you glaze the surface with too much compound.

LikeLike

I have pointed people to this article for years. Today, as part of a discussion, someone said they see very little difference between the images in the Abrasion section. I have always focused attention at the apex in that section where I see minor changes image to image. However, I do wonder why I’m not seeing much effect of burnishing in moving the metal patterns on the bevel as more stropping passes are used. Why is that?

I have always assumed that burnishing is the predominant effect; especially when stropping on leather.

LikeLike

Just joined, and greatly interested on stropping. Electron microscopy gives spectacular images, at a great cost. I have used light scattering methods. I do not run anymore a professional light scattering lab, but I would expect that a measure via optical microscopy of the (misfocused) cutting edge would provide a quantitative measure of the mean square fluctuations introduced by surface irregularities. Ofcourse one should avoid reflections, and pick up scattered light only. Sensitivity would be awesome.

LikeLike

I have A love-hate relationship with sharpening. I can get to the utility razor blade degree of sharpness on the BESS scale always. Then comes stropping which leaves me befuddled. Should my blade be pulled at a steeper or less steep angle? i.e. If I sharpen at 15 degrees should I hone at 17 degrees or 13 degrees?

LikeLike