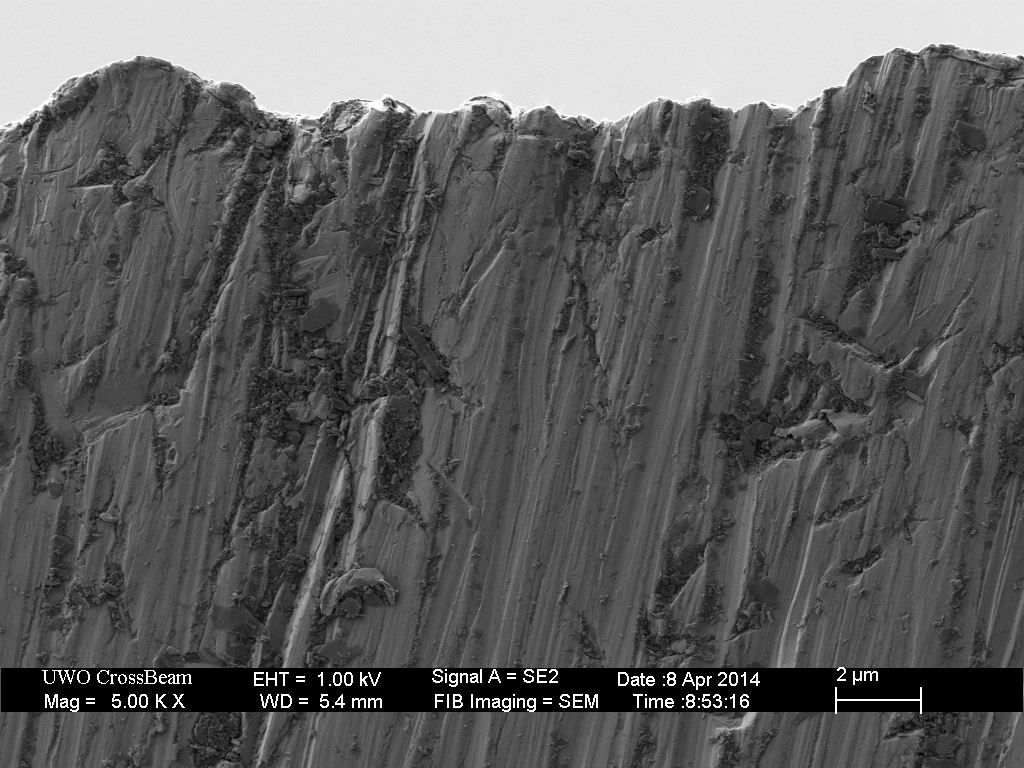

Following the bevel set on the Chosera 1k, the razor was honed on Shapton glass stones; 2k, 4k, 8k and 16k. At each step in the progression, SEM imaging was performed.

The side-view images, at 5000x magnification are shown below. As expected, scratch depth and width decrease with each step. Although the Shapton 2k is rated 7.35μm grit and the 16k is rated 0.92 μm, the observed scratch depth is much shallower, less than one tenth the grit size.

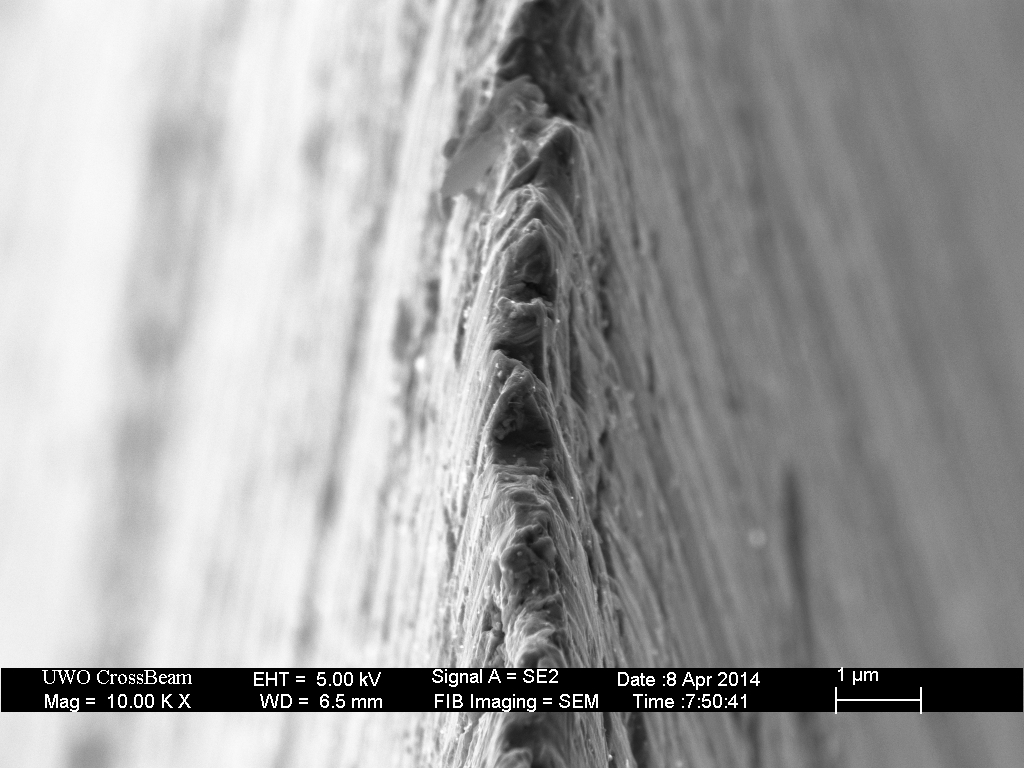

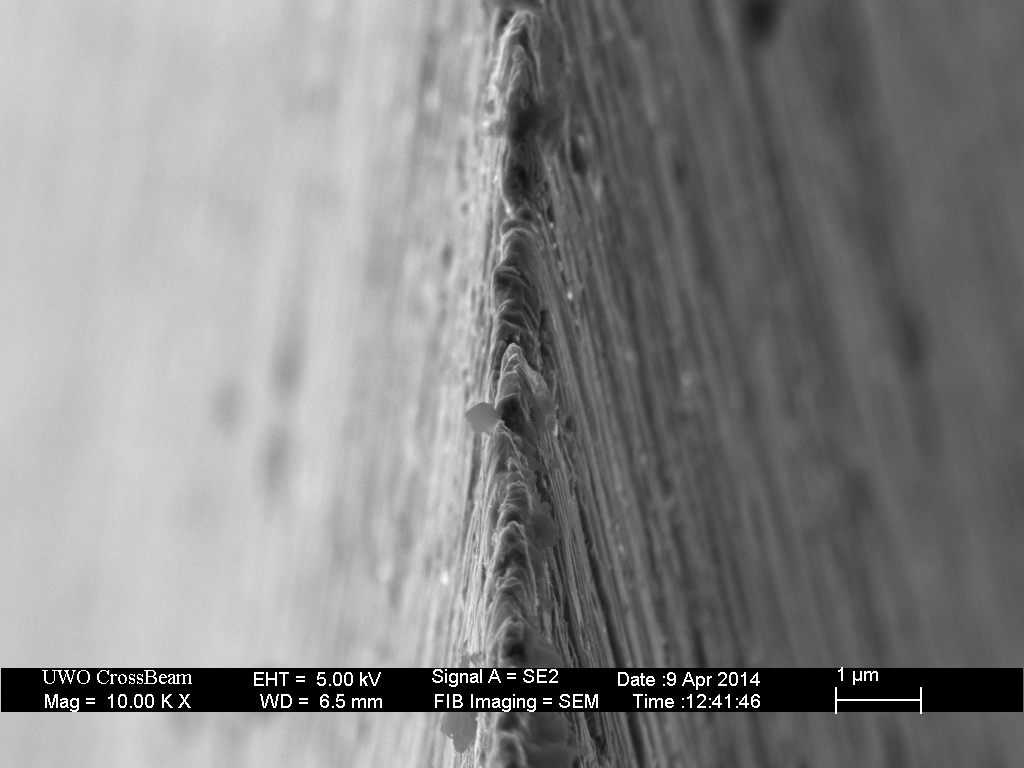

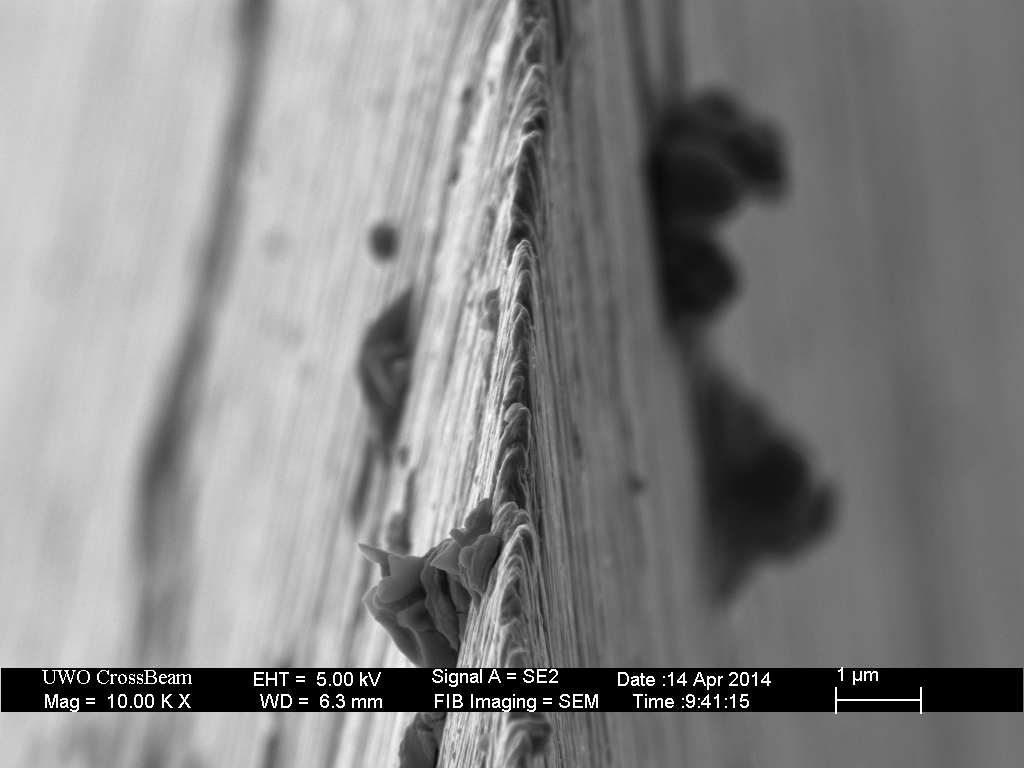

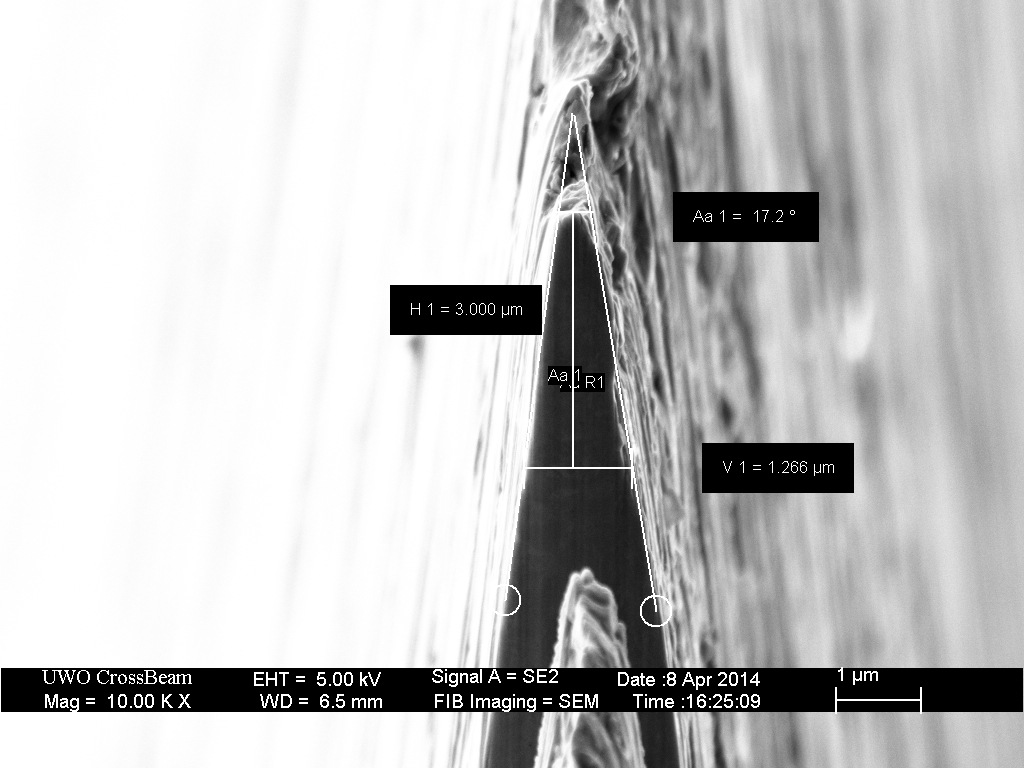

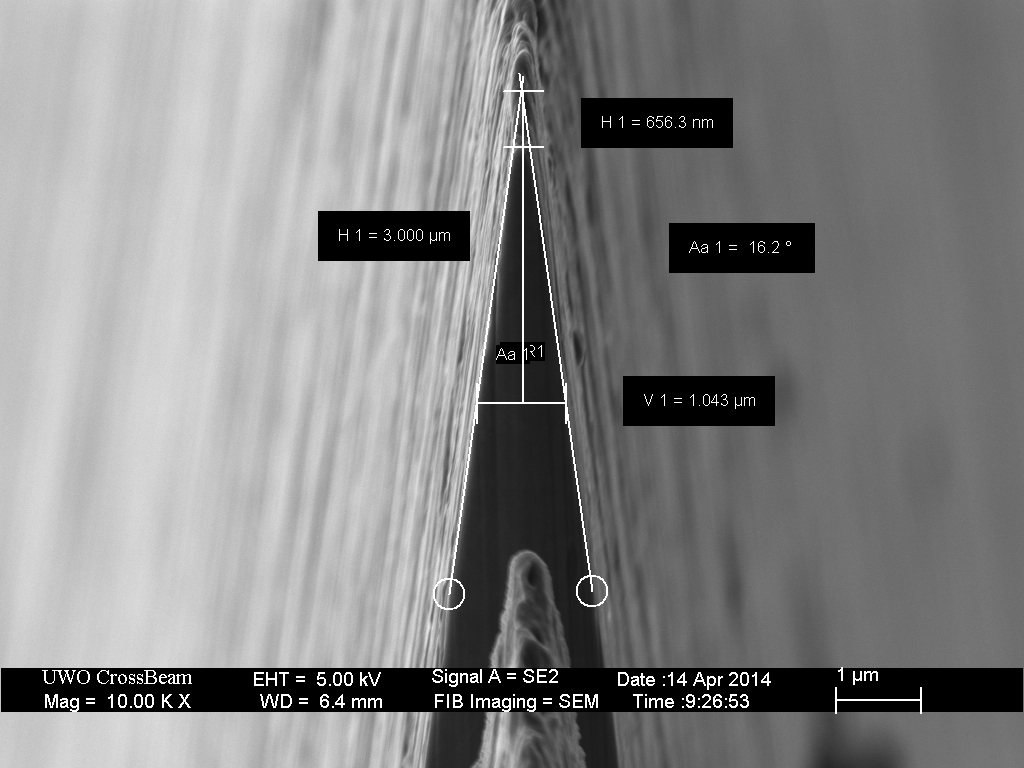

The above side-view images provide little insight into the edge geometry or keenness. Edge view images, taken at an inclined angle to provide perspective, allow direct assessment of the apex width. The edge width (or width of the apex) decreases with increasing hone grit rating.

Cross-section images for the progression are shown below.

No significant change in the bevel angle or width at 3 microns occurs after the 4k level. No measurable difference is observed between the 4k and 16k level, other than a reduction in the apex width, observed in the edge-on views (above).

The convexity near the apex is removed by the 4k level, and the measured geometry is unchanged with higher grits beyond the 4k. Beyond the 4k level, the bevel polish is refined and the edge width is reduced from about 0.3 microns to about 0.1 microns.

Sharpness is achieved during the bevel setting stage up to 4k grit. Beyond the 4k grit, Keenness improves, but Sharpness is not improved further.

34 responses to “The Honing Progression”

This is interesting because it basically shows what Cliff Stamp and Tom Blodgett have said, that a coarser edge will typically have longer edge retention because the apex width is increased vs a higher polished edge. Thanks for posting this!

LikeLike

Todd, can I post this on my website w/ reference/link to your blog?

LikeLike

Yes Josh, certainly.

LikeLike

[…] I came across this blog done by Todd Simpson which has EXCELLENT photography of knife edges. I asked Todd and he did not […]

LikeLike

Probably the most surprising result here is that the improvement beyond the 4k level is so visually underwhelming. At the same time, a dramatic improvement in performance, as measured by shave-testing, is typically observed over the same 4k-8k-16k refinement levels. The simplest explanation is that there is a keenness threshold required for comfortable shaving; an edge width in the range of 100nm.

LikeLike

Todd, are those all edge leading strokes?

LikeLike

Yes, all of these form foil-burrs with edge trailing strokes.

LikeLike

Thanking you is a bit small, as this body of work is so big! Thank you so much!!! So happy to have come by this Blog.

I’ve tried staying as scientific as possible, but could not help to ask for confirmation on the last reply to Andy. My question is in regards to the following:

Andy asked if they are all *edge leading strokes*, your reply was “Yes, all of these form foil-burrs with edge trailing strokes.”

Question: Was each foil-burr formed on EACH hone firstly with *Edge Leading Strokes* and then finished/ prepared on EACH hone, by *Edge Trailing Strokes*?

LikeLike

My comment wasn’t very clear. These are strictly edge leading results. There would be no point in doing edge trailing as they would all look basically the same with foil burrs hanging off the apex. This is an especially big problem with straight razors because of the the combination of using a low, fixed angle and low pressure, makes it easy to produce foil burrs.

LikeLike

Science (i.e. Seeing – Vision) is king.

LikeLike

On the previous article on bevel set, it was clear the diamond plate was more keen but less sharp than the Chosera. So you know if the progression here would change depending on which stone you used to bevel set?

Would the micro convexity stick around thru to the 16K or would you end up in the same place regardless of which stone you used as a bevel setter?

LikeLike

As I showed in the post “too big of a jump” you can go directly from bevel set to 16k.

You only need to remove a fraction of a micron of metal from the bevel to eliminate this degree of convexity – this can easily be achieved with the 16k (if freshly lapped and bevel-set level of force is applied).

LikeLiked by 1 person

Thank you for these awesome pictures. I have a blog and I sharpen knives by hand professionally. I have for years struggled with the “1k edge has better edge retention than a 5k edge” theory. The science was beyond me. However the photos support that. I know Tom so I’ll email him as well. Thanks again. Very Respectfully

Peter Nowlan, Nova Scotia.

LikeLike

There’s an idiot on SRP who claims “you admitted you have very little experience with honing” What do you have to say about that?

LikeLike

I’ve not kept an exact count, but I would estimate I’ve test shaved about 1000 blades and prepared more than 500 blades over the past 4 years for imaging experiments.

LikeLike

In some peoples’ head-movie, seeing the truth with images is less reliable than their own qualitative experience (understandable), and in some cases, less reliable than information that somebody else with a high post count on a shave forum told them. It’s like telling somebody that their religion is wrong because “science”.

LikeLike

It’s been my experience that many people will believe the first answer to their question and then not consider any other answer no matter how persuasive the arguments that the first answer was wrong.

I would argue that a successful scientist doesn’t believe anything absolutely. A healthy skepticism of both old and new ideas is essential to being open-minded.

Internet forums, on the other hand, are full of people who only skeptical of things that are inconsistent with their existing beliefs.

LikeLike

I would argue that ANY truly intelligent person doesn’t believe anything absolutely. I think ALL human knowledge is subject to revision with further (heretofore unknown) pertinent information. I for one truly enjoy reading this blog, and hope that there are many more installments to come.

LikeLike

I see no reason to hold conclusions in my head, I’m happy to hold a probability function. There is an x percent chance that “a,” a y percent chance that “b,” and z percent chance that “c”…with as many letters as you like and of course “i” might be some horribly messy combination of a,c…& j.

I guess we agree that those people who 1) encounter a doubt, 2) guess at the answer, and then in the next second 3) forget that there was ever any doubt…have, an unintelligent habit.

LikeLike

Hey, I wonder which stones would give me the best edge on knives that do light slice cutting tasks like kitchen knives. How far should I progress with the grits? Stropping wouldn’t make any sense in this case right?

LikeLike

I think most people would be happy with the edge from a honing rod, provided they thin their knives down to 12-15 degrees per side. Stropping can obviously produce a keener edge, but I personally don’t find it lasts long enough to be worth the effort. If I had to pick one “finishing stone” for kitchen knives it would probably be the DMT Extra Fine.

LikeLike

Tahnks for the reply. What coarse stones I use to thin my knives down is really personal preference right? Right now I use an Atoma 400 to rebevel my knives. Is there any particular reason you choose a diamond stone to finish? Why no ceramic like Spyderco for example or a waterstone like a Naniwa Chosera?

LikeLike

The DMT EF plates I own (all three of them) have a sprinkling of over-sized diamonds that quickly produce an unusually effective edge. I’m not impressed with the edges from other diamond stones in that range. The Spyderco stones and sharpmaker ceramic do not grind, they only burnish to remove metal by adhesive wear, and are essentially equivalent to a honing rod. I do think most people would be quite satisfied with those edges. The 1k Chosera can produce an edge that is much like a ceramic knife, so good slicing ability but it requires a bit of soaking and its messy and slow, so not something I’d be likely to grab.

Coarse grinding is definitely a personal preference. For a sub-$100 knife or a chisel I’d probably just use the belt sander. I’ve been experimenting with a Wicked Edge and I’m quite impressed with the 200 grit diamond for rapid removal. For a straight razor where it isn’t possible to apply enough pressure to get a coarse stone to cut, I’ll actually use the DMT EF – it’s extremely fast at low pressure. Also, I’ve found the Atoma 1200 is faster than the 400.

LikeLike

I heard that the fine and upwards grit DMT stones have quiet some large particles mixed in between them. You seem to be using that as a feature. Eventually I might look into the DMT EF you mentioned, maybe it fits my needs as well.

For guided systems, the TSProf got my attention. I think I’ll be getting one and test the Edge Pro Matrix diamond stones with it. Results look great from what I’ve seen.

Again thanks for the reply and the work you put into this site. Invaluable information!

LikeLike

I have three “fine” plates and all are quite uniform. The three extra-fine and the one extra-extra-fine have the sprinkling of larger grit particles. I might buy a medium-extra-fine plate some time when I’m feeling careless with my money, just to see.

I’m not convinced that these oversized particles aren’t added deliberately; these exist in natural stones, and I’ve found them in several manufactured stones as well.

LikeLike

I can’t enter this topic because I have no instruments neither knoledge to do that! But I have my poor experience! So I have one small big question! From a pratical point of view can you describe a typical progression honing with a specific razor and with a detailed scheme of laps for honing. I.E. 20 half strokes + 30 Circle strokes + 20 x Strokes for each progression.

It seems to me this kind of topic very interisting have no pratical application!!!! at all if you don’t put a scheme real of honing verified in a real procedure of honing!

I am the last person to jugde your work because I’m a begginer but I learnt a lot about what is theory and what is practice!

I learn for example that if I put a razor smile directly in a path of the x I will never hone enough the heal!!!!!!!!!!!!!!!!

Never seen this! Never read this! Simple experience!

What about in doing a real process for a real razor???

I have a slight “smile” razor that is not smile but has curves! That’s why I use ” Smile”!!!!!! and with this razor you can use the simple x! neither can use the x with curve for razor with little curves because the spine is too tall!

So What about geometry?? First we should speak about the geometry of razor that force use to put the razor in some positions and follow detailed paths for honing!!!!!!Or what about people putting videos on you tube and saying 16000 K shapton and 30000 K Shapton is garbage because they see overhoning!! when no one has told them what magnification have to use to see if there is overhoning on a a cutting edge??????? On you tube I have seen all and the contrary of all! No science! They are all scientists as long as they buy a microscope! But I wonder if they really know how to use it ??? I do not think so!! In fact I’m sure not! or rather they know how to use it? Yes, but do they know how to interpret it to understand what happens to the razor blade? and IF yes where have they learned all these things if they have not studied anything at all? Greetings all

All this question are to let people think iabout what they see and read!

I don’t give solutions if I’m not sure 100%

On contrary I prefer that people found the true ( pratical thins almost of all!!!) by themself and share after with others if they want!!!

LikeLike

No razor is perfectly straight, so even on a perfectly flat stone you won’t hit the entire edge on both sides. The best way to deal with this is to rock the blade when sharpening or shift the pressure from one end to the other to give the blade a slight smile geometry – also known as “honing towards a smile.” The other options are to use a narrow stone or a convex one.

LikeLike

Hi Todd

I wonder at about what width of the apex that the knife can push cut 80g paper cross the grain? Can an apex honed (edge leading) by Chosera 1000 or Shapton Glass 4000 push cut the paper cross the grain?

LikeLike

You would essentially need a shaving edge, so less than 100nm. You can make a foil with edge trailing strokes on those stones that is in that range, but it would likely fold when cutting paper.

LikeLike

I see, thanks.

LikeLike

Hi! Thanks for the detailed pictures and explanations of the Shapton Glass honing progression! I realise you no longer use this progression, and now only go up to 4k followed by your stropping method, but I am curious about your opinions regarding optimal usage of the 16k stone.

There is a lot of talk online about the Shapton Glass 16k causing “micro-chipping” due to a relatively wide particle size distribution, and thus it is a poor razor stone and more suitable for knives and chisels. Does this align with your experiences? Is it more likely caused by an overly narrow apex width and “over honing”? “Dr Matt” has a clip on Youtube relating his negative experience with this stone (https://www.youtube.com/watch?v=sn104Hib8I0).

I imagine that if that *is* the case, your pasted denim stropping technique is a better solution as the weave compensates for the wide particle size distribution of the metal polish pastes. It would be interesting to see the difference in “keenness” of the pasted denim stropping after the 4k, 8k and 16k, and whether there would be any (slight) advantage in going further up the progression, despite the “sharpness” being essentially unchanged.

Thanks for your insights.

LikeLike

The glass stones contain very large aluminum oxide particles as “filler” to provide the hardness and slow wear of these stones, and those particles also act as burnishing points, as do the large silica particles in natural stones. These large particles can cause negative issues immediately after flattening (where they are fractured and present large sharp edges), but I’ve found that effect is short lived.

There is no such thing as an “overly narrow apex.” However, it is possible to form a burr, especially with edge trailing strokes or softer steel. Almost always, what appears to be micro-chipping to low-quality optical microscopy is a burr.

In general, as you hone a razor in the edge leading direction on this type of stone the edge micro-chips at sub-micron scale preventing the formation of a burr. In general, the higher the grit, the smaller the scale of that micro-chipping. I’ve shown that quite clearly in this article.

LikeLike

Thanks! That was really useful! 🙂

LikeLike

Good day!

First of all, I want to express my deep gratitude to you for the work you doing here. It is an eye opener for me as sharpening hobbyist. Finally after reading tons of contradictory articles from gurus, I can just see what is happening with the steel and start to build my own mental model on what and when should I do during the sharpening, instead of blindly following instructions.

One thing I could not find anywhere in your articles (sorry if I’ve missed it) is your test or opinion on jointing. It is when you deburr blade like dragging it through wood, as was explored here, but using highest grit stone instead of wood. It’s like intentional micro-dulling of the apex by dragging blade lightly over the stone under it’s own weight. And then couple stropping moves are performed same as in the case with the wood.

I see this technique here and there in articles and videos. E.g. with knife in “The Carter-Stanley Method of Sharpening: Chapter 3 The Extended Method” at 35:36. I also see people doing it to razors (and calling it “technical barrier” in my language segment of internets).

Would be great to hear your opinion on that.

Thank you!

LikeLike